Stainless Steel Guide Shell

Stainless Steel Guide Shell

El Stainless Steel Guide Shell is engineered for exceptional durability and corrosion resistance in demanding industrial environments. Designed for precision and reliability, the Stainless Steel Guide Shell ensures optimal performance and long-lasting efficiency in high-pressure systems.

El Stainless Steel Guide Shell is engineered for exceptional durability and corrosion resistance in demanding industrial environments. Designed for precision and reliability, the Stainless Steel Guide Shell ensures optimal performance and long-lasting efficiency in high-pressure systems.

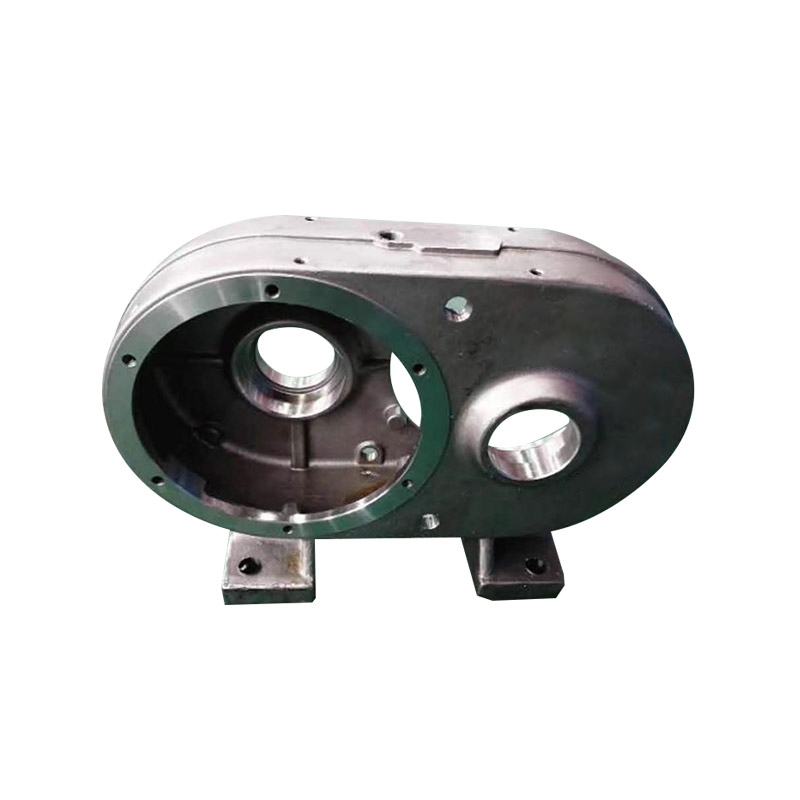

The Stainless Steel Guide Shell is expertly engineered to provide outstanding structural strength, corrosion resistance, and dimensional stability in the most demanding industrial environments. Whether used in high-pressure pumps, turbine systems, or chemical processing units, the Stainless Steel Guide Shell plays a critical role in guiding fluid flow and maintaining mechanical alignment under harsh operating conditions.

Crafted from high-grade stainless steel, this guide shell resists rust, pitting, and chemical degradation, even when exposed to aggressive media, elevated temperatures, or fluctuating pressures. Its robust construction ensures a longer service life, reducing the frequency of maintenance and system downtime. The precise machining of the Stainless Steel Guide Shell contributes to minimal friction loss, efficient energy transfer, and consistent system performance.

Designed with both reliability and operational efficiency in mind, the Stainless Steel Guide Shell enhances pump and turbine functionality by ensuring smooth internal flow paths and supporting internal rotating components with unmatched accuracy. This translates to reduced vibration, less wear on moving parts, and improved equipment longevity.

When system integrity, corrosion resistance, and high-performance operation are critical, the Stainless Steel Guide Shell stands out as a dependable component. Explore our full range today to find the ideal solution for your industrial flow control systems.

- More than 60 kinds of materials, more than a dozen alloys, and 70 kinds of numbers.

- Many products can be produced, 3500+ precision casting molds, 1000+ sand casting molds.

- The production accessories can be large or small.

- A single product of 50 kg can be customized.

- Multiple furnaces are available for selection, and single pieces of 50 kg to 850 kg can be produced.

- 20 years of master, rich experience, entered the industry in the 1980s, the industry leader.

- Products are traceable, and each furnace product has a certificate: 3.1 Material Certificate.

- Customers can ask a third-party testing agency to issue a 3.2 certificate.

- Processing fine products can be issued with a processing certificate.