Comparing Popular 3D Printing Materials

Welcome to My Blog!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

Table of Contents

Introduction

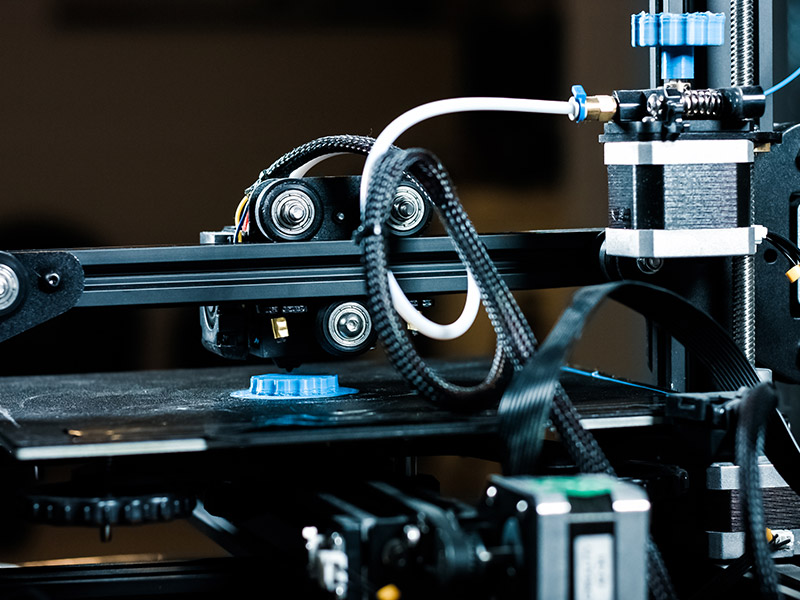

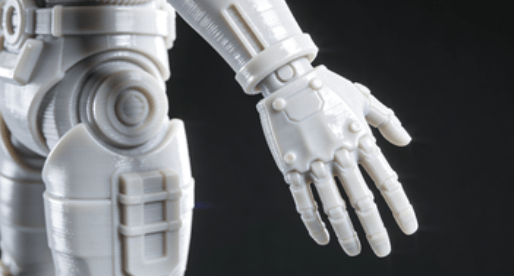

Additive manufacturing, or 3D printing, is no longer just a prototyping tool—it has become an essential technology in aerospace, automotive, healthcare, and consumer product industries. At the core of every successful print is the choice of 3D printing materials. Selecting the right material influences strength, flexibility, temperature resistance, surface finish, and cost. A poor material choice can lead to warping, cracking, or premature part failure, highlighting the importance of understanding the options available. This guide explores the most popular 3D printing materials, their characteristics, applications, and practical considerations, helping both beginners and professionals make informed choices.

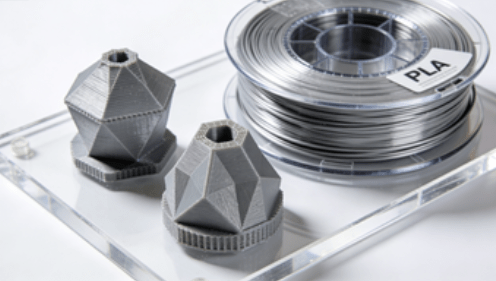

Thermoplastics: Popular Everyday Materials

Thermoplastics remain the most common materials for FDM and FFF printing. PLA is widely used for its ease of printing, biodegradability, and accuracy, making it suitable for models, decorative items, and educational projects. ABS provides higher strength and temperature resistance, ideal for functional parts, but requires a heated bed to prevent warping. PETG strikes a balance between strength, flexibility, and chemical resistance, making it suitable for mechanical parts and everyday functional prints. Nylon is favored for its toughness and abrasion resistance, though it requires careful drying to avoid moisture-related issues.

Resins: High-Detail and Engineering Applications

Photopolymer resins are used in SLA and DLP printers for applications requiring high-resolution surfaces and fine details. Standard resins deliver smooth finishes but are brittle, while engineering resins offer enhanced strength, toughness, and heat resistance for functional prototypes and tooling. High-temperature resins maintain structural integrity at elevated temperatures, making them ideal for demanding applications. Resins are widely used in dental models, jewelry, and visual prototypes where precision and surface quality are critical.

Composites: Enhanced Strength and Performance

Composite filaments combine thermoplastics with fibers or powders to improve stiffness, strength, or other functional properties. Carbon fiber composites increase rigidity while keeping parts lightweight, suitable for engineering prototypes and automotive components. Glass fiber reinforcement enhances dimensional stability and reduces shrinkage. Metal-filled filaments provide a metallic appearance and some additional weight, though they do not match true metal mechanical properties. Composites are especially useful when high performance is required but metal printing is impractical.

Metal Materials: Industrial Strength

Metal additive manufacturing includes stainless steel, titanium alloys, and aluminum powders, typically processed through selective laser melting or direct metal laser sintering. Metal prints achieve tensile strengths comparable to traditional cast or forged parts, often exceeding 500 MPa in stainless steel. They are suitable for aerospace, medical implants, and high-load components. Metal 3D printing provides design flexibility, reducing assembly parts and enabling complex geometries impossible with conventional manufacturing.

Flexible Materials: Soft and Resilient

Flexible filaments like TPU offer elasticity and impact resistance. These materials are used in wearables, phone cases, soft robotics, and gaskets. Flexible materials require specialized printer settings and slower print speeds but allow designers to produce parts that move, bend, and absorb impact without breaking. They expand the application range of 3D printing beyond rigid prototypes and models.

Comparing Popular 3D Printing Materials

| Material Type | Tensile Strength (MPa) | Heat Deflection Temp (°C) | Cost per kg (USD) | Typical Applications |

|---|---|---|---|---|

| PLA | ~37 | 60–65 | 20–30 | Models, prototypes, educational prints |

| ABS | ~40 | ~105 | 25–35 | Functional prototypes, enclosures |

| PETG | ~50 | 70–80 | 30–45 | Durable mechanical parts |

| Nylon | 60+ | 75–100 | 50–80 | Gears, bearings, industrial components |

| Standard Resin | ~30 | ~50 | 50–80 | High-detail visual models |

| Engineering Resin | 50+ | 100–200+ | 80–150 | Functional prototypes, tooling |

| Carbon Fiber Filament | 70+ | 80–100 | 80–120 | Lightweight, stiff parts for engineering |

| Metal (316L) | 500+ | 500+ | 250–400 | Load-bearing metal parts, aerospace |

| TPU | N/A (elastic) | 40–80 | 40–70 | Wearables, flexible components |

| High-Temp Polymer | 80–100+ | 180–220+ | 300–500 | Aerospace, high-performance engineering |

This table highlights the range of mechanical properties, heat resistance, and cost across popular 3D printing materials. Consumer filaments like PLA and PETG are affordable and versatile, while composites, resins, and metals meet the requirements of demanding professional applications.

Material Selection Factors in Practice

Choosing the best 3D printing materials depends on several considerations. Functional requirements, such as strength, flexibility, or temperature tolerance, dictate the choice. Printer compatibility is another key factor, as some materials require specialized hardware, heated chambers, or direct-drive extruders. Post-processing requirements, like curing, sanding, or sintering, affect workflow efficiency. Cost remains critical, as high-performance polymers and metals are significantly more expensive than consumer-grade filaments. Finally, environmental impact is increasingly relevant, with PLA and recycled PETG offering eco-friendly alternatives.

Industry Insights and Expert Opinions

Material scientists and engineers emphasize that part performance should guide material selection. Structural or load-bearing parts demand materials with high tensile strength and thermal resistance, whereas visual models prioritize detail and surface finish. Environmental experts recommend considering biodegradable or recyclable filaments where possible. Industry leaders predict that multi-material printing, high-performance polymers, and functionally graded materials will define the next decade of additive manufacturing, enabling parts with integrated sensors or hybrid mechanical properties.

Real-World Applications and Case Studies

In automotive prototyping, carbon fiber composites reduced weight by 30% while maintaining rigidity for structural mounts. Dental labs use engineering resins to produce molds with precise dimensions, reducing post-processing by 40%. Aerospace engineers employ titanium alloy printing for critical components, consolidating complex assemblies into single parts and maintaining regulatory compliance.

Conclusion

The choice of 3D printing materials directly affects print quality, functionality, and overall project success. Thermoplastics are ideal for beginners and low-stress prototypes, while resins, composites, and metals meet industrial demands. Flexible filaments broaden application possibilities for wearable and impact-resistant parts. Selecting the right material involves understanding mechanical requirements, printer capabilities, cost, and post-processing needs. With informed choices, designers and engineers can maximize the potential of additive manufacturing for professional, hobbyist, and industrial applications.

FAQ

Q: Which 3D printing materials are best for beginners?

PLA and PETG are recommended for beginners due to ease of use, low cost, and wide printer compatibility.

Q: Can metal 3D printing materials be used on desktop printers?

Metal printing requires industrial equipment like SLM or DMLS systems and is generally not suitable for home printers.

Q: Are flexible filaments difficult to print?

Flexible materials require slower print speeds and fine-tuned settings but enable wearable and soft robotics applications.

Q: How can I improve the mechanical performance of my prints?

Using reinforced composites, adjusting print orientation, increasing infill percentage, or adopting hybrid manufacturing approaches can enhance strength.

Q: Are there environmentally friendly 3D printing materials?

Yes, PLA is biodegradable, and recycled PETG offers a sustainable option without compromising print quality.

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF