9 Powerful Reasons to Choose Carbon Steel Investment Casting

Welcome to My Blog!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

Table of Contents

Blog Key Points

- What carbon steel investment casting is and why it matters

- 9 powerful reasons to choose this process

- Technical concepts: material properties, precision, and durability

- Comparative analysis with other manufacturing methods

- Real-world case studies and industry applications

- Cost analysis, ROI, and maintenance strategies

- Environmental and sustainability considerations

- FAQ addressing common search queries

- Expert opinions and authoritative references

Introduction

In today’s highly competitive industrial landscape, manufacturers demand precision, durability, and efficiency in every component they produce. Carbon steel investment casting has emerged as a game-changing solution, enabling the creation of complex, high-performance components with minimal waste.

According to Dr. James Patel, a senior metallurgist at the American Foundry Society, “Carbon steel investment casting combines mechanical strength, repeatability, and geometric flexibility, making it ideal for applications ranging from aerospace to automotive and heavy machinery. Companies that adopt this process often see a significant reduction in downtime and post-processing costs.”

This comprehensive guide explores 9 powerful reasons to choose carbon steel investment casting, enriched with technical data, comparisons, case studies, and practical guidance for engineers, designers, and procurement professionals.

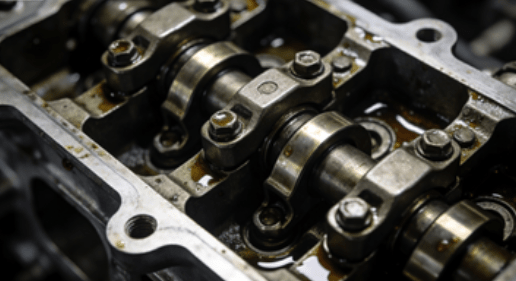

1. Exceptional Strength and Durability

Concept: Carbon steel delivers high mechanical strength for demanding environments.

- Heat-treated carbon steel can achieve tensile strengths over 700 MPa and yield strengths around 400–500 MPa.

- High carbon variants offer enhanced wear resistance, while low carbon types provide better ductility.

Applications: Heavy machinery parts, automotive gears, industrial shafts.

Expert Insight: Dr. Maria Lopez, Materials Engineer, notes: “For components subjected to cyclical loads or high impact, carbon steel investment casting provides superior fatigue resistance compared to conventional casting methods.”

Key Benefits:

- High load-bearing capacity

- Long operational life under heavy stress

- Resistance to wear and fatigue

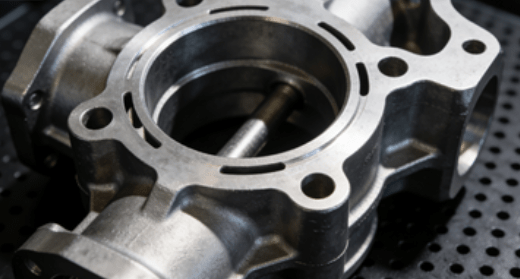

2. Precision and Complex Geometry

Concept: Achieve intricate shapes without compromising structural integrity.

- Investment casting can produce internal cavities, undercuts, and thin walls with tolerances as tight as ±0.1 mm.

- Smooth surface finish reduces the need for post-processing.

Example Applications: Turbine blades, valve bodies, precision brackets.

Advantages:

- Minimizes machining costs

- Enables advanced mechanical designs

- Reduces assembly steps

3. Cost-Effective Production

Concept: Reduce overall manufacturing costs through efficiency.

- Net-shape casting minimizes waste and machining.

- Studies indicate up to 30% savings for complex components compared to CNC machining from solid billets.

Applications: Medium-to-high volume automotive parts, aerospace brackets, energy equipment.

Cost-Effectiveness List:

- Reduced raw material waste

- Lower machining and labor costs

- Shorter production lead times

4. Excellent Material Versatility

Concept: Adaptable to various carbon steel grades.

- Low carbon steel (0.05–0.25% C): High ductility, ideal for structural components.

- Medium carbon steel (0.25–0.55% C): Balanced strength and hardness.

- High carbon steel (0.55–1.0% C): Excellent wear resistance, suited for high-load applications.

Benefit List:

- Customizable mechanical properties

- Wide range of hardness and toughness

- Supports diverse industrial applications

5. Superior Surface Finish

Concept: Minimize finishing and machining requirements.

- Typical surface roughness Ra: 1.6–3.2 µm.

- Less post-casting polishing or grinding required.

Applications: Decorative metal parts, valve bodies, precision gears.

Advantages:

- Reduced labor costs

- Faster time-to-market

- High-quality visual appearance

6. Reduced Material Waste

Concept: Efficient use of carbon steel for sustainability and cost savings.

- Material utilization exceeds 90%, compared to ~60–70% for traditional machining.

- Supports eco-friendly manufacturing by minimizing scrap.

Environmental Insight: Less scrap reduces landfill impact and energy usage.

Applications: Automotive engine components, industrial machinery parts.

7. Enhanced Reliability and Consistency

Concept: Repeatable high-quality production for industrial standards.

- Uniform mechanical properties across batches

- Minimal defects due to precise mold and controlled casting environment

Applications: Safety-critical automotive parts, aerospace brackets, industrial valves.

Expert Opinion: Dr. Robert Kim, Mechanical Engineer, states: “Consistency in tensile and yield strength is critical for components under cyclical loads. Carbon steel investment casting delivers predictable results.”

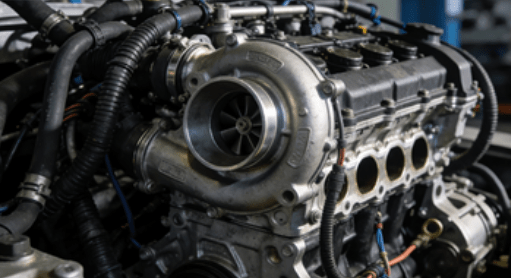

8. Wide Industrial Applications

Concept: Applicable across multiple sectors.

Industries and Components:

- Automotive: Engine blocks, gears, brake components

- Aerospace: Structural brackets, housings, fasteners

- Mining & Heavy Equipment: Shafts, gears, structural supports

- Energy: Turbine parts, pump housings, valves

Benefit: One casting process meets the requirements of multiple industries, reducing tooling and process costs.

9. Environmentally Friendly and Sustainable

Concept: Reduce waste, energy use, and support green manufacturing.

- High material yield

- Recyclable carbon steel

- Reduced machining and energy consumption

Sustainability List:

- Minimizes scrap

- Reduces CO₂ emissions

- Supports eco-conscious manufacturing initiatives

Comparison Table: Carbon Steel Investment Casting vs Other Methods

| Feature | Carbon Steel Investment Casting | CNC Machining | Sand Casting | Forging |

|---|---|---|---|---|

| Material Waste | Low (<10%) | High (~30–40%) | Medium | Medium |

| Complex Geometry Capability | Excellent | Moderate | Low | Low |

| Surface Finish | High | Medium | Low | Medium |

| Cost for Complex Parts | Moderate | High | Low | High |

| Repeatability & Consistency | Excellent | High | Medium | Medium |

| Environmental Impact | Low | Medium | High | Medium |

Maintenance Tips for Long-Lasting Components

- Proper Heat Treatment: Ensures optimal hardness and toughness.

- Regular Inspection: Detect micro-cracks or surface defects early.

- Controlled Environment: Avoid extreme corrosion conditions to extend part life.

- Lubrication and Coatings: For moving assemblies, ensure appropriate lubrication to reduce wear.

Case Studies

Automotive Engine Components

- Carbon steel investment casting reduced post-machining by 40%

- Yielded consistent tensile strength across 10,000+ units

Industrial Valves

- Components experienced zero failures over 5-year operation

- Material efficiency improved by 25%

Aerospace Brackets

- Achieved ±0.05 mm tolerance

- Reduced assembly time due to high dimensional accuracy

FAQ

What is carbon steel investment casting used for?

It’s used for producing high-precision, durable components in automotive, aerospace, energy, and heavy machinery.

How does it compare to sand casting?

Investment casting provides better surface finish, tighter tolerances, and lower material waste than sand casting.

Can it produce complex geometries?

Yes, intricate shapes, undercuts, and thin-walled components are achievable.

How long do these components last?

With proper material selection and heat treatment, components can last decades under industrial use.

Is it environmentally sustainable?

Yes. High material utilization, reduced machining, and recyclable steel make it eco-friendly.

Conclusion

Carbon steel investment casting combines strength, precision, versatility, and sustainability, making it ideal for modern manufacturing. Its nine powerful benefits—from exceptional durability to environmental advantages—demonstrate why it remains a top choice across industries.

By leveraging this technology, manufacturers can reduce costs, improve efficiency, and deliver reliable components, ensuring both operational success and long-term sustainability.

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF