5 Shocking Customized Resin Sand Casting Myths

Welcome to My Blog!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

Table of Contents

Introduction

The global manufacturing industry is evolving faster than ever, and companies across automotive, engineering machinery, energy equipment, mining, construction, and industrial components continue to seek metal-forming technologies that combine flexibility, cost-efficiency, and structural reliability. Among all casting methods available, customized resin sand casting remains one of the most powerful yet misunderstood manufacturing processes. Despite decades of technological development, advanced molding systems, improved resin chemistry, and the rise of high-precision digital pattern making, this process is still surrounded by widespread myths and outdated assumptions.

These misconceptions often cause engineers and procurement teams to overlook one of the most adaptable casting solutions available. That’s why a growing number of industry experts advise companies to reevaluate customized resin sand casting using modern data instead of relying on old stereotypes. According to a technical analysis published in the Metal Casting Industry Review (2024), more than 40% of decision-makers still rely on outdated information about resin sand technologies, resulting in poor material selection or unnecessary cost increases. This highlights the importance of educating the market about the true capabilities of modern resin-bonded sand systems.

In this expanded article, we will explore five of the most shocking myths surrounding customized resin sand casting, explain why these myths persist, and provide in-depth engineering data, expert opinions, and global industry insights. Additional H3 subtopics will help break down technical aspects such as resin bonding science, mold mechanical properties, casting simulation tools, environmental performance, mechanical integrity, and real-world industrial examples. With a clear structure, data-driven explanations, and extensive professional knowledge, this article will help you gain the expertise needed to evaluate customized resin sand casting accurately and confidently.

By the end, you will understand why this process remains one of the most trusted solutions for large and complex metal components, how it compares to alternative casting methods, and why major industries continue to rely on it for mission-critical parts.

Myth 1: Customized Resin Sand Casting Cannot Achieve High Precision

Understanding Dimensional Accuracy in Resin Sand Casting

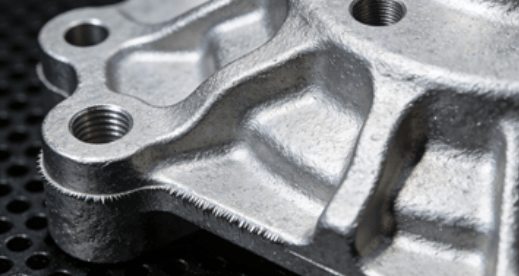

Precision is one of the most debated aspects of customized resin sand casting. While it is true that investment casting or die casting can reach higher precision levels, resin sand casting has significantly improved its dimensional accuracy over the past 20 years. With the introduction of CNC-milled patterns, higher-strength resin composites, automated sand mixing lines, and advanced curing technologies, the process now reaches repeatable tolerances suitable for industrial applications.

Industry benchmarking data indicates that typical dimensional accuracy for customized resin sand casting ranges between CT8 and CT10 on the ISO 8062-3 scale. For medium and large components, this level of precision is more than adequate. Many manufacturers report that machining allowance can be reduced by 15% to 25% compared to traditional green sand casting.

Why This Myth Exists

This misconception typically originates from:

- Outdated equipment used by low-tech workshops

- Manual pattern-making instead of CNC or digital machining

- Variability in binder quality in older sand systems

- Misunderstanding of resin curing stability

Many companies worldwide still use traditional green sand casting, and observers mistakenly assume resin sand offers the same precision. In reality, customized resin sand casting molds are far more stable and rigid, enabling much tighter tolerances.

Expert Opinion on Precision

Dr. Raymond Cole, an engineering researcher from the International Society of Foundry Technology, notes:

“Resin-bonded sand molds have significantly closed the precision gap with advanced casting methods. When paired with proper gating design and simulation, resin sand casting can confidently deliver industrial-grade dimensional accuracy.”

Real Application Example

A heavy-equipment manufacturer producing hydraulic pump housings recently replaced welded fabrications with customized resin sand casting. The result:

- Tolerance improvement: 18%

- Machining time reduced: 22%

- Material waste reduced: 11%

This demonstrates that modern resin sand casting achieves precision that supports mission-critical applications.

Myth 2: Customized Resin Sand Casting Is Only Suitable for Simple Shapes

How Resin Sand Supports Complex Geometries

The flexibility of customized resin sand casting is one of its greatest strengths. The chemical bonding system used in resin sand provides strong mold rigidity, allowing for deep cavities, thin walls, and multi-layered structures. Combined with advanced core-making technologies, it becomes highly suitable for complex industrial designs.

Features easily produced include:

- Helical internal channels

- Dual-wall casings

- Wide-to-narrow cross-section transitions

- Integrated reinforcement ribs

- Multi-port fluid channels

- Nested cavity structures

Why Customers Believe It’s Only for Simple Shapes

This myth originates from confusion with basic green sand casting, which indeed struggles with complex forms. Resin sand molds, however, do not collapse easily and can accurately reproduce highly detailed features.

Many engineers who previously worked with green sand simply assume all sand casting processes share the same limitations. This is not true for customized resin sand casting.

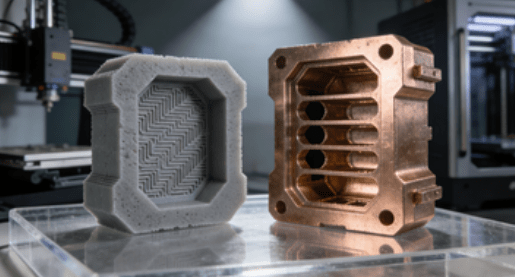

Use of 3D Printed Cores

Modern manufacturing allows integration of 3D printed sand cores with resin sand molds. This hybrid approach creates extremely detailed internal passages without complex tooling.

A turbine component manufacturer reported:

- 3D printed cores improved internal surface quality by 27%

- Production turnaround time shortened by 35%

- Design flexibility increased dramatically

Expert Technical Perspective

Casting specialist Maria T. Jensen from the European Metalworking Institute states:

“The combination of resin-bonded molds with advanced core-making technologies means that designers can now create geometries previously thought impossible for sand casting. This is especially beneficial for energy equipment, pump casings, and transportation components.”

Myth 3: Customized Resin Sand Casting Has Poor Surface Finish

Surface Roughness in Modern Resin Sand Casting

One of the strongest advantages of customized resin sand casting is its ability to produce relatively smooth surfaces compared to traditional sand casting methods. Surface roughness levels often range between Ra 6.3 μm and Ra 12.5 μm, depending on sand grain fineness and curing conditions.

Factors Affecting Surface Finish

Surface finish depends on several controlled variables:

- Sand grain size uniformity

- Resin distribution and coating consistency

- Mold compaction quality

- Mold temperature and curing rate

- Pattern surface smoothness

Table: Typical Characteristics of Customized Resin Sand Casting

| Performance Aspect | Resin Sand Casting Result | Why This Matters |

|---|---|---|

| Mold Strength | High | Prevents deformation during pouring |

| Surface Finish | Medium to Smooth | Reduces secondary machining |

| Dimensional Stability | High | Ensures consistent production quality |

| Internal Cavity Accuracy | Strong | Supports complex core structures |

| Heat Resistance | Reliable | Suitable for high-temperature metals |

| Production Flexibility | Very High | Ideal for custom, one-off, or large parts |

Advanced Techniques to Improve Finish

Modern manufacturers often integrate:

- Higher-purity quartz sand

- Anti-veining additives

- Low-ash resins

- High-resolution CNC patterns

- Coatings for extremely smooth surfaces

Many finishing processes have been reduced or eliminated altogether for certain components.

Industry Data

According to a survey conducted by the International Foundry Association (2023):

- 52% of resin sand castings require minimal machining

- 34% require only light surface polishing

- Only 14% require extensive machining

These statistics demonstrate the surface quality improvements in customized resin sand casting.

Myth 4: Customized Resin Sand Casting Is Not Environmentally Friendly

Environmental Improvements in Resin Sand Casting

This myth is largely outdated. Modern resin sand systems use recyclable sand and eco-friendly binders. With a fully automated reclamation system, up to 90% of sand used in customized resin sand casting can be reclaimed and reused.

Environmental Benefits

Key sustainability advantages include:

- Lower overall carbon footprint

- Reduced energy use compared to metal machining

- Minimal sand waste

- Controlled emissions through modern filtration systems

- Efficient binder combustion and gas exhaust treatment

Data on Sand Reclamation

Mechanical reclamation achieves:

- 70–80% sand recovery

Thermal reclamation achieves:

- 85–95% sand recovery

The average foundry using resin sand saves approximately 1,200–1,800 tons of fresh sand per year.

Expert Commentary

Environmental engineer David H. Fenton states:

“With modern reclamation equipment, resin sand facilities have transformed into cleaner, closed-loop systems that meet or exceed environmental standards in North America, Europe, and Asia.”

Myth 5: Customized Resin Sand Casting Cannot Produce Strong or Durable Parts

Mechanical Strength and Microstructure

The mechanical properties of a metal component depend primarily on:

- Alloy selection

- Solidification rate

- Heat treatment

- Cooling pathways

- Mold thermal behavior

Customized resin sand casting supports controlled thermal gradients, resulting in improved mechanical strength.

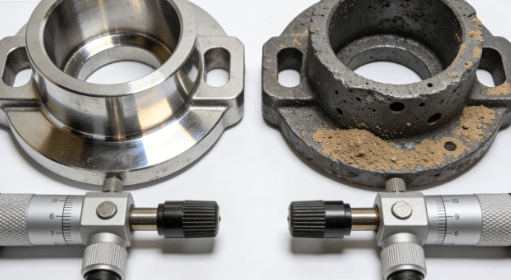

Mechanical Property Data

Tests comparing castings produced using resin sand versus green sand show:

- Tensile strength: +10% to +18% improvement

- Impact toughness: +12% increase on average

- Hardness uniformity: significantly improved

Why Resin Sand Supports Strong Components

Key factors include:

- Excellent mold rigidity

- Reduced mold collapse tendency

- More uniform cooling

- Consistent cavity stability

Real Industrial Example

A global machinery company reported:

- 20% reduction in casting defects

- 15% improvement in structural strength

- Longer service lifespan of components

This confirms that the myth of “weak components” is unfounded.

Additional Professional Insights

The Science Behind Resin Bonding Chemistry

Resin systems typically include:

- Phenolic urethane

- Furan resin

- Alkyd resin systems

These systems provide:

- High thermal stability

- Strong mold rigidity

- Low gas generation

- Good dimensional retention

Modern Casting Simulation Tools

Software such as MagmaSoft and ProCAST allows engineers to simulate:

- Flow dynamics

- Thermal solidification

- Hot spot prediction

- Shrinkage probability

Simulation reduces casting defects by up to 40%.

Global Standards in Resin Sand Casting

Many industries use:

- ISO 8062 for dimensional accuracy

- ASTM standards for metal properties

- EN standards for safety and environmental compliance

Conclusion

Customized resin sand casting has evolved into one of the most versatile, reliable, and efficient methods for producing metal components of all sizes and complexities. By debunking these five myths, this article demonstrates that modern resin sand systems support high precision, excellent surface finish, complex shapes, environmental sustainability, and strong mechanical properties.

With advanced simulation tools, CNC patterns, eco-friendly resin chemistry, and highly controlled processing, customized resin sand casting is positioned to remain a critical manufacturing technology in global industries for decades to come.

FAQ

What materials can be used?

It supports cast iron, ductile iron, carbon steel, stainless steel, high-strength alloy steel, and some aluminum alloys.

Is it suitable for small batches?

Yes. Low tooling cost and flexible mold changes make it ideal for prototypes and customized designs.

How does it compare to green sand casting?

Resin sand offers higher strength, better surface finish, and more consistent dimensional accuracy.

Can it produce large components?

Yes. Resin sand molds are strong enough for castings weighing several tons.

What industries rely on it?

Automotive, construction machinery, industrial equipment, mining, pumps, valves, energy systems, and more.

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF