Ductile Iron Castings Quality Checklist: A Practical Guide for Buyers

Welcome to My Blog!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

Table of Contents

Key Points

- Understand the essential quality indicators of ductile iron castings

- Learn how to inspect raw material, microstructure, mechanical properties, and dimensions

- Compare ductile iron castings with gray iron and steel to guide buying decisions

- Identify common casting defects and prevention methods

- Learn real factory inspection techniques and testing standards

- Get a complete quality checklist for procurement and quality control

- Understand how to evaluate suppliers based on certifications, process, and traceability

Introduction

Imagine your factory receives a batch of ductile iron castings for valve bodies, pump housings, or automotive parts. At first glance, everything seems normal. But after a few weeks in service, several parts fail due to cracks, internal porosity, or low tensile strength. The cost is not only the replacement parts, but also downtime, labor, and reputation loss.

This scenario happens frequently because buyers often rely on price or appearance alone. In reality, ductile iron castings are highly dependent on metallurgical structure, heat treatment, and process control. A strong quality checklist is the difference between a reliable supply chain and constant production risk.

This guide is designed for procurement managers, engineers, and quality professionals. It provides a complete checklist and practical steps to evaluate ductile iron castings. You will learn what to check, how to verify it, and how to avoid common mistakes.

What Are Ductile Iron Castings

Definition and Basic Concept

Ductile iron castings are iron alloys that contain spherical graphite nodules. The graphite shape changes from flake to nodular through nodulizing treatment. This change significantly improves strength and ductility.

Why Ductile Iron Castings Are Widely Used

Ductile iron castings are widely used because they offer:

- High tensile strength and impact resistance

- Good fatigue performance

- Excellent machinability

- Cost efficiency compared to steel

The Key Metallurgical Feature

The key feature is the graphite nodules. If nodules are not uniform or are irregular, the casting will lose ductility and become brittle. This is why microstructure inspection is essential.

Why Quality Matters in Ductile Iron Castings

Reliability and Safety

Ductile iron castings are often used in pressure systems, structural components, and moving parts. Failure can cause:

- Equipment shutdown

- Safety incidents

- Significant economic loss

Cost Control and Long Term Performance

Poor quality castings lead to:

- High scrap rates

- Rework and machining waste

- Short service life

- Increased maintenance frequency

Market Demand and Product Performance

In modern industrial applications, customers demand stable performance and long life. Ductile iron castings with unstable quality cannot meet these requirements.

Ductile Iron Castings Quality Checklist

Material and Chemical Composition Check

What to Verify

Chemical composition determines the final performance. Key elements include:

- Carbon

- Silicon

- Manganese

- Magnesium

- Sulfur

- Phosphorus

Acceptable Ranges

Typical composition ranges for ductile iron castings:

- Carbon 3.2 to 3.8

- Silicon 1.8 to 3.0

- Manganese 0.1 to 0.6

- Magnesium 0.03 to 0.05

- Sulfur less than 0.03

- Phosphorus less than 0.05

Why This Matters

If magnesium is insufficient, graphite will form as flakes and the casting will become brittle. If sulfur is too high, nodules cannot form properly.

Microstructure Inspection

Graphite Nodules and Matrix

Microstructure inspection should include:

- Nodule count per square millimeter

- Nodule shape and size

- Matrix structure such as ferrite, pearlite, or martensite

What High Quality Looks Like

High quality ductile iron castings show:

- Uniform nodules

- Nodule count typically above 30 per square millimeter

- Minimal carbide content

Heat Treatment Effects

Heat treatment such as normalizing improves toughness and stability. A proper heat treatment will:

- Refine grain size

- Reduce residual stress

- Improve ductility

Mechanical Properties Verification

Tensile Strength and Elongation

Common mechanical properties for ductile iron castings:

- Tensile strength 400 to 700 MPa

- Elongation 10 to 25 percent

- Hardness 170 to 300 HB

Why This Matters

Mechanical properties indicate the casting can withstand real world load and stress. Low elongation means the casting is brittle and may crack under impact.

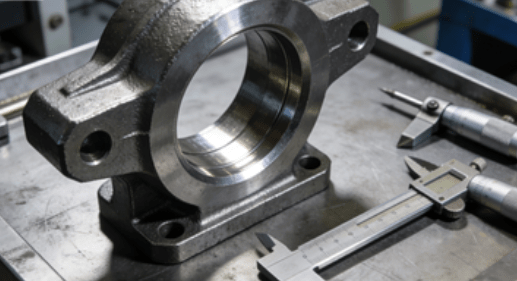

Dimensional and Surface Inspection

Dimensional Accuracy

Use tools such as:

- Calipers

- Micrometers

- CMM coordinate measuring machine

- Laser scanning

Surface Quality

Check for:

- No cracks

- No sand holes

- Smooth surface

- Correct machining marks

Dimensional Tolerance

Typical tolerance depends on casting size and complexity. Common standards are:

- ISO 8062 for dimensional tolerances

- GB standards for casting tolerances

Non Destructive Testing NDT

Common NDT Methods

- Magnetic particle testing

- Ultrasonic testing

- Dye penetrant testing

- X ray inspection

When to Use NDT

NDT is required for critical components such as:

- Valve bodies

- Pump housings

- Pressure pipe fittings

- Automotive load bearing parts

What NDT Reveals

NDT can detect:

- Internal porosity

- Cracks

- Inclusions

- Cold shuts

Comparison Ductile Iron Castings vs Gray Iron vs Steel

Strength and Toughness Comparison

Ductile iron castings provide a balanced performance between gray iron and steel.

| Material | Strength | Ductility | Cost | Best For |

|---|---|---|---|---|

| Ductile iron castings | High | High | Medium | Valves, gears, housings |

| Gray iron | Medium | Low | Low | Basic casings |

| Steel | Very high | Medium | High | Heavy duty components |

Why Buyers Choose Ductile Iron Castings

- Better toughness than gray iron

- More cost effective than steel

- Excellent machinability

- High fatigue resistance

Common Defects and How to Identify Them

Porosity

Porosity is caused by gas trapped in the casting or shrinkage. It reduces strength and causes leakage in pressure parts.

Cold Shuts and Inclusions

Cold shuts occur when molten metal does not fuse properly. Inclusions are non metallic impurities. Both reduce strength and may cause cracks.

Cracks and Warping

Cracks often occur during cooling or machining. Warping indicates uneven stress distribution or poor heat treatment.

How to Prevent Defects

- Ensure correct melt temperature

- Use proper gating system

- Control mold permeability

- Use proper inoculation and nodulizing process

- Conduct heat treatment correctly

Real Factory Inspection Checklist

Melting Furnace and Metal Treatment

- Check furnace type and temperature control

- Verify nodulizing and inoculation process

- Inspect raw material source and traceability

Molding and Casting Process

- Check sand quality and molding accuracy

- Verify mold curing time

- Inspect gating and riser design

Heat Treatment Facility

- Confirm heat treatment temperature and time

- Check cooling method and equipment

- Verify temperature control and records

Quality Inspection Laboratory

- Check availability of spectrometer

- Verify tensile testing machine

- Confirm metallographic microscope

- Check NDT equipment

Industry Standards and Quality Requirements

Common Standards Used in Ductile Iron Castings

- ISO 1083 ductile iron standard

- ASTM A536 ductile iron casting standard

- GB 1348 ductile iron standard

- EN 1563 ductile iron casting standard

Typical Quality Requirements for Critical Components

For pressure components and heavy machinery, quality requirements often include:

- Tensile strength above 500 MPa

- Elongation above 12 percent

- NDT inspection for all parts

- Strict dimensional control

Expert Opinions and Industry Insights

Metallurgy Expert View

A senior metallurgist from a leading casting company said:

“Graphite morphology determines the ductile iron casting quality. Even with correct composition, poor nodulizing will lead to flaky graphite and brittle failure.”

Engineering Expert View

A mechanical engineer working in pump manufacturing said:

“Material testing and microstructure inspection must be done before mass production. Many failures are caused by inconsistent microstructure and poor heat treatment.”

Quality Manager View

A quality manager in valve manufacturing said:

“Traceability and documentation are essential. If the supplier cannot provide heat treatment report and NDT report, the casting should not be accepted.”

How to Choose a Reliable Supplier

Supplier Evaluation Checklist

- Production capacity and stable output

- Technical team and quality management

- Test equipment and inspection system

- Ability to provide full documentation

- ISO and industry certifications

Key Supplier Questions

- How do you control nodulizing process

- What is your defect rate and scrap rate

- Do you have NDT capability

- Can you provide sample testing

- What is your heat treatment process

Practical Buyer Checklist

Before Purchase

- Verify material certificate

- Confirm chemical composition

- Check mechanical properties

- Review microstructure report

- Confirm dimensional tolerance

After Receiving Goods

- Conduct sample testing

- Perform visual inspection

- Check surface finish

- Verify NDT results

- Check packaging and transportation protection

Practical Application and Cost Control

How Quality Impacts Cost

High quality ductile iron castings may cost more initially but reduce:

- Rework cost

- Scrap cost

- Failure cost

- Maintenance cost

Long Term Performance

A high quality ductile iron casting can last 10 to 20 years in many applications such as water valves, pump housings, and structural parts.

Additional Comparison Tables

Material Performance Comparison

| Property | Ductile Iron Castings | Gray Iron | Steel |

|---|---|---|---|

| Tensile strength | High | Medium | Very high |

| Ductility | High | Low | Medium |

| Fatigue resistance | High | Low | High |

| Cost | Medium | Low | High |

| Machinability | Good | Good | Medium |

Inspection Priority Table

| Inspection Type | Priority | Why |

|---|---|---|

| Chemical composition | High | Determines final properties |

| Microstructure | High | Determines ductility and strength |

| Mechanical test | High | Confirms performance |

| NDT | Medium to High | Critical parts need internal inspection |

| Dimensional check | High | Ensures fit and function |

Conclusion

Ductile iron castings quality is determined by multiple factors including composition, microstructure, mechanical properties, and manufacturing process control. For buyers, a comprehensive checklist is essential to ensure reliability and long term performance.

By following this guide, you can:

- Reduce defects and failure risk

- Improve production stability

- Control cost effectively

- Ensure safe and reliable performance

If you want, I can also help you:

- Create a custom supplier evaluation checklist

- Write a factory audit template

- Recommend inspection standards based on your application

Just tell me your application and requirements, and I will tailor the guide to your needs.

FAQ

What is the most important factor in ductile iron castings quality

The most important factor is microstructure, especially graphite nodules and matrix distribution. It directly determines strength and ductility.

How can I ensure the casting meets mechanical requirements

Request tensile test, hardness test, and microstructure report. Compare results with your design standards.

Why is NDT important for ductile iron castings

NDT detects internal defects such as porosity, cracks, and inclusions that cannot be seen visually. For pressure parts, NDT is mandatory.

How to choose between ductile iron castings and steel

Choose ductile iron castings if you need high toughness, good fatigue resistance, and cost efficiency. Choose steel for extreme strength and high temperature applications.

How long do ductile iron castings last

Under normal conditions, high quality ductile iron castings can last 10 to 20 years. In harsh environments, proper coating and maintenance are required.

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF