Avoid Common Casting Impeller Pump Issues: A Comprehensive Guide

Welcome to My Blog!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

Table of Contents

Introduction

Casting impeller pumps are critical components in many industrial and municipal systems, from water treatment plants to chemical processing facilities. Despite their robust construction, these pumps are not immune to problems that can reduce efficiency, shorten lifespan, or even lead to catastrophic failures. In this comprehensive guide, we explore the most common issues encountered with casting impeller pumps, preventive strategies, design considerations, and expert insights to help engineers, plant managers, and buyers make informed decisions.

Key Takeaways of This Blog:

- Understand frequent problems in casting impeller pumps

- Learn preventive maintenance techniques and best practices

- Explore material selection, design, and operational factors

- Compare casting impeller pumps with other impeller materials

- Access data, expert opinions, and practical recommendations

- Answer common questions with a user-focused FAQ section

Understanding Casting Impeller Pump Basics

What is a Casting Impeller Pump?

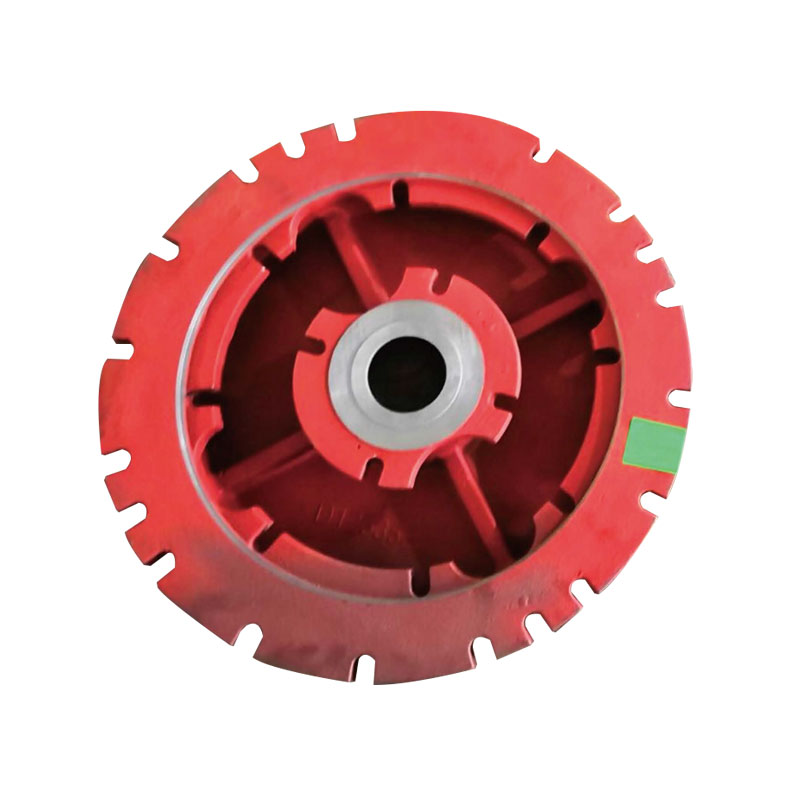

A casting impeller pump is a centrifugal pump where the impeller is manufactured using a casting process. Casting ensures the impeller has uniform material properties, can withstand high pressures, and resists erosion from abrasive fluids. This type of pump is commonly used in industries such as wastewater treatment, chemical processing, mining, and power generation.

Key Components of a Casting Impeller Pump

- Impeller: The central component responsible for transferring energy to the fluid.

- Pump Casing: Guides fluid efficiently while protecting the pump’s internal components.

- Shaft and Bearings: Maintain alignment and reduce mechanical wear.

- Seals and Gaskets: Prevent fluid leakage and maintain operational safety.

Why Casting Matters

Casting allows for intricate impeller designs that are difficult to achieve with machining. According to industry data, cast impellers have a 20–30% higher resistance to cavitation damage compared to fabricated impellers. Materials like high-chrome iron and duplex stainless steel are commonly used to extend pump life under abrasive and corrosive conditions.

Common Issues in Casting Impeller Pumps

Cavitation Problems

Cavitation occurs when local pressure drops below the vapor pressure of the liquid, forming vapor bubbles that collapse violently on the impeller surface. This can result in pitting, noise, vibration, and reduced efficiency.

Expert Insight: Dr. Michael Thompson, a pump design specialist, notes: “Cavitation is often misunderstood. Monitoring inlet conditions and maintaining proper NPSH (Net Positive Suction Head) is crucial to prevent damage.”

Wear and Erosion

Continuous flow of abrasive fluids, such as sand-laden water, can cause erosion of the impeller vanes. Choosing wear-resistant alloys like high-chrome iron can increase operational life by up to 50%. Regular inspection of wear patterns helps anticipate maintenance needs.

Imbalance and Vibration

An unevenly cast impeller or improper installation can cause imbalance. Even minor imbalance leads to increased bearing wear, higher vibration levels, and eventually mechanical failure. Laser alignment tools and vibration monitoring systems can help detect early signs.

Leakage Concerns

Seal or gasket failures are common causes of leakage in casting impeller pumps. Selecting the correct seal material and type (mechanical, lip, or packing) for the fluid type and temperature is critical. Regular checks can prevent fluid loss and environmental hazards.

Overheating and Shaft Damage

Extended operation at high temperatures or dry running can damage the pump shaft. Using thermal sensors and proper lubrication prevents premature wear and reduces downtime.

Maintenance Strategies to Prevent Pump Issues

Regular Inspection and Cleaning

Monthly visual inspections of the pump casing, impeller, and bearings prevent small problems from escalating. Debris or sediment accumulation can severely impact efficiency if not removed promptly.

Lubrication and Bearing Care

Bearing failure is one of the leading causes of casting impeller pump downtime. Using the correct type and quantity of lubricant, and adhering to manufacturer recommendations, is essential.

Monitoring Performance Metrics

Key performance indicators such as flow rate, differential pressure, vibration amplitude, and energy consumption should be tracked. Early detection of anomalies allows for timely intervention.

Implementing Predictive Maintenance

Predictive maintenance, using vibration analysis and thermography, can reduce unexpected failures by 30–40%. Modern monitoring systems can alert operators to signs of wear before catastrophic damage occurs.

Material Selection and Design Considerations

Choosing the Right Material

Common materials include:

- High-Chrome Iron: Excellent for abrasive fluids

- Stainless Steel: Resistant to corrosion, ideal for chemicals

- Bronze or Duplex Alloys: Good for marine and wastewater applications

Impeller Design Impact

- Closed Impellers: Better efficiency and reduced cavitation

- Open Impellers: Easier maintenance but more prone to erosion

- Semi-Open Impellers: Compromise between maintenance and performance

Surface Treatments

Surface treatments like nickel plating, epoxy coating, or thermal spraying improve resistance to corrosion and erosion. Studies show that coated impellers can extend service life by 25–35%.

Casting Impeller Pump vs Other Impeller Types

| Feature | Casting Impeller Pump | Stainless Steel Pump | Fabricated Impeller Pump |

|---|---|---|---|

| Cost | Moderate | High | Moderate to Low |

| Durability | High for abrasive fluids | Excellent for corrosive fluids | Moderate |

| Manufacturing | Casting process | Machined/welded | Fabricated from plates |

| Maintenance | Requires routine inspection | Easier to clean | Can require more frequent adjustment |

| Application | Industrial, water, slurry | Chemicals, food, corrosive fluids | Low-to-medium stress fluids |

Comparison Insight:

If your application involves abrasive slurry, a casting impeller pump is often more cost-effective than a stainless steel alternative. For corrosive chemicals, stainless steel may be necessary despite the higher cost.

Advanced Operational Considerations

Pump Alignment and Installation

Proper alignment during installation prevents premature bearing failure. Laser alignment tools are recommended for precise results.

Controlling Operating Conditions

Maintaining correct temperature, flow, and pressure prevents cavitation, overheating, and vibration issues. Variable frequency drives (VFDs) can adjust pump speed to match system demand.

Handling Abrasive and Corrosive Fluids

Installing filters and strainers upstream of the pump reduces the risk of erosion. Monitoring fluid pH and chemical composition ensures long-term reliability.

Expert Opinions and Case Studies

- Dr. Sarah Collins, Pump Engineer: “Routine maintenance and proper material selection can double the life of a casting impeller pump in mining operations.”

- Case Study: A water treatment facility reduced pump failures by 45% after implementing vibration monitoring and high-chrome impellers for abrasive sludge.

FAQ

How do I detect cavitation in my casting impeller pump?

Unusual noises, vibration, or fluctuating flow rates are common indicators. Measuring NPSH and maintaining proper inlet conditions are preventive strategies.

How often should a casting impeller pump be inspected?

Monthly visual inspections and an annual detailed check are recommended for industrial pumps.

Can a casting impeller pump be retrofitted with a stainless steel impeller?

Yes, but consider the fluid type, installation space, and cost implications. Stainless steel impellers resist corrosion but may have different performance curves.

What materials reduce wear in casting impeller pumps?

High-chrome iron and duplex alloys are effective. Surface treatments like nickel plating further reduce erosion.

Are predictive maintenance tools worth the investment?

Yes, predictive tools can reduce unplanned downtime by up to 40% and extend pump life, improving ROI over time.

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF