3D Printed Car Parts: Complete Guide for OEM, Aftermarket, and Manufacturing Applications

Table of Contents

Introduction

3D printing is transforming automotive engineering, enabling faster prototyping, lightweight construction, and highly customizable manufacturing. As the industry shifts toward EV innovation and flexible production, 3d printed car parts are becoming essential across OEM, aftermarket, and supplier pipelines. This guide provides full technical insight for engineers, tuning specialists, and automotive manufacturers.

What Are 3D Printed Car Parts?

3D-printed car parts are components produced through additive manufacturing, where the material is built layer-by-layer instead of removed through cutting.

This method unlocks new geometries, reduces assembly complexity, and eliminates mold costs—ideal for rapid development and low-volume production.

Key Concepts of Additive Manufacturing

Additive manufacturing enables structural optimization, internal channels, and multi-part integration.

The result is lighter, stronger, and more efficient components than traditionally machined designs.

Why 3D Printed Car Parts Matter in Modern Automotive Engineering

Lightweight Engineering

Lattice and hollow structures reduce weight up to 40% while maintaining strength, improving performance and efficiency for EVs and motorsports.

Design Freedom

Engineers can incorporate ducts, hinges, reinforcement ribs, and cooling channels that can’t be produced with traditional tooling.

Cost Efficiency

For prototypes or small-batch components, eliminating molds cuts development costs dramatically and accelerates iteration times.

3D Printing Technologies Used for Car Parts

FDM (Fused Deposition Modeling)

FDM is the most accessible 3D printing method, widely used for early-stage prototyping and low-stress automotive components.

It works by heating and extruding thermoplastic filaments layer-by-layer to form solid parts.

This method is ideal for dashboard panels, brackets, wiring mounts, and custom interior fittings.

Because materials like ABS, ASA, and carbon-fiber-reinforced nylon are available, engineers can create concept parts that simulate real-world structure and geometry at minimal cost. While FDM does not match the precision of industrial systems, it offers fast turnaround and excellent flexibility during design iteration cycles.

SLS (Selective Laser Sintering)

SLS uses a high-powered laser to fuse powdered nylon (PA12, PA11, PA6) into dense, functional components without needing support structures.

This makes it particularly suitable for under-hood parts, mechanical housings, durable clips, and snap-fit components.

Due to its high thermal resistance and impact strength, SLS is often used for airflow ducts, EV battery components, and automotive connectors.

Its ability to produce highly complex shapes with consistent mechanical properties makes it one of the most reliable additive manufacturing solutions for automotive manufacturers and suppliers.

SLA (Stereolithography)

SLA uses UV lasers to cure liquid resin into extremely detailed, high-resolution parts.

It is ideal for producing smooth prototypes, lens covers, interior trim elements, and intricate design-validation models.

Because SLA parts can achieve micron-level accuracy, designers often use them to test ergonomics, visual fit, and lighting assemblies before committing to production.

Although SLA resins are not as heat-resistant as nylon or metal, new engineering-grade resins provide improved tensile strength and temperature stability for more demanding automotive applications.

MJF (Multi Jet Fusion)

MJF is an industrial-grade technology known for its material strength, superior dimensional accuracy, and consistent surface quality.

It uses a combination of fusing agents and heat energy to bind nylon powder, allowing fast production of durable components.

This technology is especially useful for EV cooling ducts, complex mechanical housings, fluid management parts, and structural brackets.

MJF delivers parts with isotropic strength, making them reliable for both prototype and end-use applications in automotive systems.

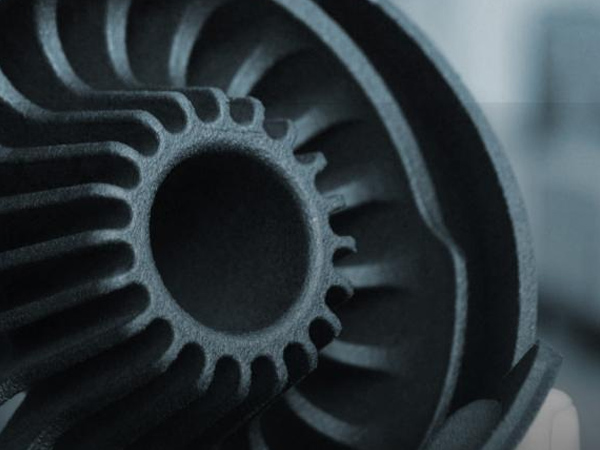

Metal 3D Printing (SLM/DMLS)

Metal additive manufacturing—commonly SLM (Selective Laser Melting) or DMLS (Direct Metal Laser Sintering)—creates high-strength metal components from powdered alloys such as aluminum, titanium, and stainless steel.

This is the preferred choice for motorsport-grade parts, engine mounts, custom intake manifolds, and lightweight structural components.

Because metal 3D printing supports lattice structures, engineers can reduce weight while maintaining—or even improving—mechanical strength compared with traditional machined parts.

SLM and DMLS are also used for heat-resistant exhaust components, turbo housings, and brackets subjected to extreme loads.

Materials Used for 3D Printed Automotive Components

Material Comparison Table

(This table appears in the required middle section of the article.)

| Material | Process | Properties | Automotive Use |

|---|---|---|---|

| PA12 Nylon | SLS / MJF | Durable, heat-resistant | Housings, ducts, interior parts |

| ABS / ASA | FDM | Impact & UV-resistant | Dashboard parts, trims |

| TPU | FDM / SLS | Flexible, shock-absorbing | Seals, vibration dampers |

| Carbon-Filled Nylon | SLS / FDM | High stiffness & light weight | Performance upgrades |

| Aluminum AlSi10Mg | SLM | Strong, lightweight | Engine brackets, racing parts |

| Stainless Steel 316L | DMLS | Heat + corrosion resistant | Exhaust components |

How 3D Printed Car Parts Are Manufactured

Digital Design & Optimization

The manufacturing of 3D Printed Car Parts always begins with a digital engineering model.

Using advanced CAD tools, designers optimize internal geometries, integrate reinforcement ribs, and apply topology optimization to remove unnecessary material.

This process allows engineers to create lightweight yet structurally reliable components such as airflow guides, cooling ducts, motor brackets, and aerodynamic surfaces.

Algorithms can also simulate heat distribution, airflow behavior, or vibration loads, helping ensure each part meets automotive durability requirements even before printing begins.

Slicing & Build Preparation

Once the design is finalized, slicing software converts the model into hundreds or thousands of printable layers.

The system calculates laser scanning paths, fusing agent deposition patterns, support structures (for SLA or metal printing), and ideal build orientation.

Proper slicing ensures:

- High dimensional accuracy

- Smooth surfaces where needed

- Strong internal bonding

- Reduced print failures during production

For complex 3D Printed Car Parts like intake manifolds, battery pack components, or under-hood clips, optimized slicing can significantly influence heat-resistance and load-bearing performance.

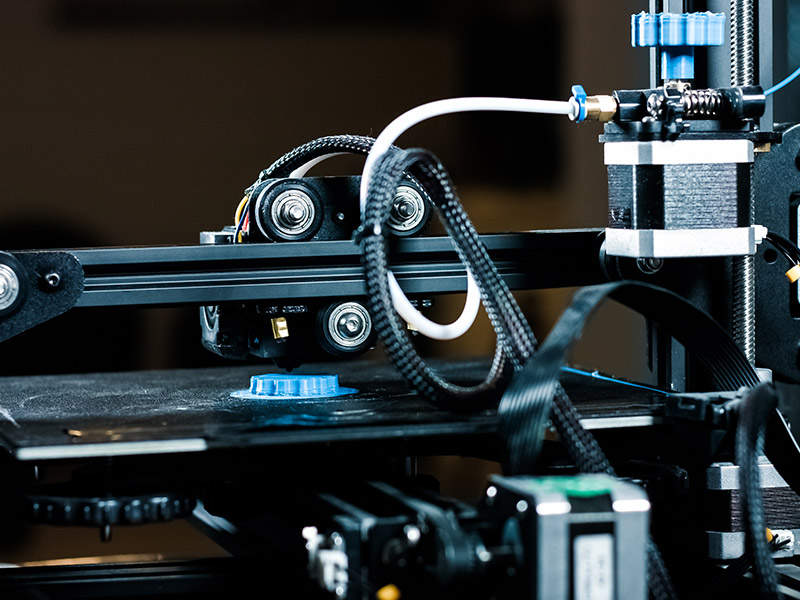

Industrial Printing Process

During printing, industrial-grade machines carefully control temperature, powder density, laser intensity, and extrusion flow.

Whether using MJF, SLS, FDM, or metal additive manufacturing, stable environmental conditions ensure parts meet OEM safety and durability standards.

Real-time monitoring systems track:

- Powder bed fusion uniformity

- Layer adhesion

- Chamber temperature

- Material shrinkage patterns

- Build anomalies or deformation risks

These controls are especially important for functional 3D Printed Car Parts used in EV systems, air-handling ducts, crash-zone prototypes, and drivetrain components.

Post-Processing for Automotive-Grade Performance

Once printing is complete, parts undergo a series of finishing processes to achieve production-ready quality.

Common steps include:

Depowdering

High-pressure air and automated stations remove loose powder from internal channels and complex geometries.

Support Removal

Metal or SLA-printed parts require careful removal of printed supports to maintain precision.

CNC Finishing

Critical surfaces—seal faces, mounting points, or bearing interfaces—may be CNC-machined for exact tolerances.

Vapor Smoothing

Improves aerodynamic surfaces and creates near-injection-molded quality for visible interior parts.

Dyeing / Surface Coloring

Custom colors help match interior themes or branding elements for aftermarket kits.

Heat Treatment or Annealing

Applied especially to metal and nylon parts to stabilize mechanical properties and improve load resistance.

Through these steps, 3D Printed Car Parts can achieve OEM-level performance and are validated for real-world automotive integration.

OEM Case Study: EV Battery Cooling Duct

Challenge

A Chinese EV manufacturer needed rapid iterations of a cooling duct. Traditional tooling required over one month—too slow for prototype testing.

3D Printed Solution

Using MJF PA12:

- Delivered in 48 hours

- 37% weight reduction

- Optimized airflow through redesigned channels

Outcome

Development time reduced by 80%, accelerating EV validation and improving thermal management.

Aftermarket Case Study: Aerodynamic Upgrade Kit

Objective

A tuning company required customizable splitters, canards, and wing brackets.

Why 3D Printing Worked

- No mold investment

- Shape personalization

- Carbon-filled nylon for motorsport rigidity

Result

Lead time reduced from months to two weeks, with verified aerodynamic performance at over 240 km/h.

Supplier Perspective: How 3D Printing Manufacturers Ensure Quality

Calibration & Quality Control

Industrial manufacturers of 3D Printed Car Parts rely on precise calibration of machines to guarantee consistent performance.

Laser power, chamber temperature, and powder or filament density are monitored in real-time to meet strict automotive standards.

Advanced monitoring systems detect layer misalignment, warping, or density inconsistencies during printing.

This ensures each batch of 3D Printed Car Parts meets tight tolerances, essential for functional components like battery ducts, drivetrain brackets, and suspension mounts.

Material Testing

Materials used in 3D printing are rigorously tested before production.

High-strength polymers, carbon-reinforced nylons, or metallic powders are validated for:

- Tensile strength and elongation

- Fatigue resistance under cyclic loading

- Dimensional accuracy after post-processing

Manufacturers often produce test coupons alongside actual 3D Printed Car Parts to measure performance metrics under simulated real-world conditions.

This process is especially critical for parts subjected to vibration, thermal stress, or mechanical loads in EVs, performance cars, and heavy-duty vehicles.

Traceability

Industrial 3D printing suppliers maintain full traceability for every production run.

Each batch of 3D Printed Car Parts comes with:

- Material certificates verifying composition

- Dimensional inspection reports

- Detailed process logs including printer settings, layer thickness, and post-processing parameters

This ensures compliance with OEM standards and supports aftermarket customers who require proof of quality for functional upgrades or custom components.

Comparison: 3D Printed vs Traditional Car Parts

Production Flexibility

3D printing supports high complexity and customization; injection molding suits mass production.

Speed

Additive manufacturing delivers functional parts in as little as 1–3 days.

Cost Structure

Ideal for low-volume products without mold costs—perfect for prototyping or aftermarket customization.

Real-World Applications of 3D Printed Car Parts

EV Development

Cooling ducts, battery enclosures, and airflow components.

Interior Customization

Mounts, trim components, and housings.

Performance & Racing

Lightweight brackets, air intake systems, and structural reinforcements.

Manufacturing Tools

Custom jigs, fixtures, and assembly aids.

FAQ

Are 3D printed car parts durable for real driving?

Yes. Industrial SLS, MJF, and metal prints meet automotive mechanical standards.

Can broken OEM parts be replaced with 3D printing?

Yes for interior components, housings, clips, and low-load brackets.

Structural replacements require engineering evaluation.

How much do 3D printed car parts cost?

Small parts: $10–$30

Functional components: $50–$300

Metal parts: $150–$600+

Can 3D printed parts withstand engine heat?

Nylon composites: 120–150°C

Metals: up to 600°C depending on alloy.

Conclusion

3D printing is reinventing how automotive parts are designed and manufactured. From OEM prototyping to aftermarket modifications and supplier manufacturing workflows, 3d printed car parts offer unmatched flexibility, speed, and engineering possibility. As EV and lightweight design evolve, the role of additive manufacturing will only grow stronger.

Stay Connected with Us

Thank you for reading! We hope this blog provided you with valuable insights and inspiration on acoustic panel ceilings. If you enjoyed the content and want to stay updated with the latest trends, tips, and behind-the-scenes updates, we’d love to connect with you on social media.

📘 Follow us on Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Join our growing community where we share expert advice, product highlights, and interactive discussions with professionals and design enthusiasts from around the world.

Let’s keep the conversation going—see you there!

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF