How Green Sand Casting Reduces Waste and Improves Efficiency in Metal Parts Manufacturing

Table of Contents

Introduction

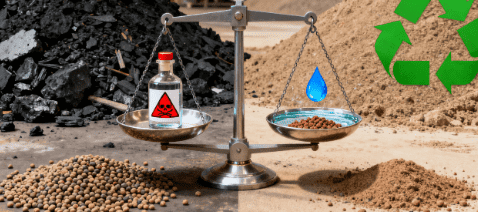

Green sand casting, a traditional yet innovative technique, plays a crucial role in the metal parts manufacturing industry. By leveraging a mixture of sand, clay, water, and other additives, green sand casting reduces waste and enhances efficiency compared to other casting methods. This process is not only cost-effective but also environmentally friendly, offering numerous advantages in the production of durable metal components. In this blog, we will explore how green sand casting contributes to sustainability, reduces waste, and improves overall efficiency, ultimately benefiting manufacturers and their customers alike.

What is Green Sand Casting?

Green sand casting is a molding technique where a mixture of sand, clay, water, and other additives is used to create a mold for casting metal parts. Unlike other types of sand casting, green sand is “green” because it has not been chemically hardened. The wet sand mixture is compacted around a pattern, and once the metal is poured into the mold, the sand mold retains its structure until it is broken away to reveal the final product. This process is widely used in industries like automotive, aerospace, and industrial equipment manufacturing due to its versatility and cost-effectiveness.

Key Features of Green Sand Casting

- Reusability of Sand: Green sand can be reused multiple times, which drastically reduces waste.

- Cost-Effective: The materials used in green sand casting are relatively inexpensive.

- Flexibility: It can be used for casting a wide range of metals including iron, steel, and aluminum.

- Environmental Benefits: The use of natural materials and minimal waste makes it a more eco-friendly option than many other casting processes.

How Green Sand Casting Reduces Waste

1. Material Reusability

One of the most significant ways green sand casting reduces waste is through the reuse of sand. After each casting, the sand can be reclaimed, cleaned, and reused in subsequent production cycles. This reduces the need for new raw materials and lowers the environmental impact of sand extraction and disposal. In fact, studies have shown that reclaimed sand can be reused for multiple casting cycles without significant degradation in performance.

2. Reduced Material Waste in Molding Process

Green sand molds are highly efficient in material usage. Unlike other processes that may require significant material waste during mold formation, green sand casting uses minimal amounts of sand that are carefully compacted around the pattern to form a mold. This ensures that the material used is directly related to the shape of the final cast, minimizing the waste generated during the casting process.

3. Minimal Chemical Waste

While green sand casting involves the use of clay and other additives, these materials do not produce significant chemical waste. Furthermore, many green sand casting operations have adopted more sustainable additives, reducing the environmental impact of the process. The absence of harmful chemicals in the sand mixture makes green sand casting one of the most environmentally friendly casting methods available.

4. Efficient Mold Design

The use of advanced technologies and precise molding techniques helps in designing molds that require less material. For instance, 3D printing and other modern technologies allow for the design of highly detailed molds that maximize the use of green sand. This level of precision reduces the amount of sand required for each mold, further minimizing waste.

How Green Sand Casting Improves Efficiency

1. Faster Production Time

Green sand casting is known for its relatively fast turnaround time compared to other methods. The wet sand mixture allows for faster molding and quicker metal cooling times. This means that manufacturers can produce more parts in a shorter amount of time, improving overall production efficiency. Additionally, because green sand molds do not require drying or curing time, production lines can be more streamlined.

2. Lower Energy Consumption

Compared to other casting methods, green sand casting requires less energy. The absence of an energy-intensive curing process helps reduce overall energy consumption. For manufacturers looking to minimize energy costs and reduce their carbon footprint, green sand casting offers an ideal solution. Additionally, because the molds are not chemically bonded, they do not require as much heat to melt and pour the metal, further contributing to energy savings.

3. Less Equipment and Setup Costs

Another advantage of green sand casting is its relatively low investment in equipment and setup. The simplicity of the process means that fewer specialized machines and equipment are required, which lowers capital expenditures for manufacturers. Furthermore, the flexibility of green sand casting allows for quick retooling and adaptation to different designs, making it a versatile choice for companies that require a broad range of metal parts.

4. Improved Quality Control

Due to the ability to reuse sand and the precision in mold design, green sand casting often results in parts with higher dimensional accuracy. Reduced defects and increased consistency in the casting process mean fewer defective parts, less rework, and a more efficient production line. By improving the quality control of the finished product, manufacturers can reduce the time spent on sorting and reworking defective parts, ultimately boosting overall efficiency.

Green Sand Casting vs. Other Casting Methods

| Casting Method | Material Cost | Energy Consumption | Waste Generation | Production Speed | Reusability of Materials |

|---|---|---|---|---|---|

| Green Sand Casting | Low | Low | Low | Fast | High |

| Investment Casting | High | Medium | Medium | Medium | Low |

| Die Casting | High | High | High | Fast | Low |

| Lost Foam Casting | Medium | Medium | Medium | Medium | Low |

The table above compares green sand casting with other popular casting methods. As shown, green sand casting stands out in terms of material cost, energy consumption, and waste generation. Its high reusability of materials makes it a more sustainable option compared to other methods.

Benefits of Green Sand Casting for Manufacturers

1. Cost Savings

The combination of low material costs, reusability of sand, and reduced energy consumption makes green sand casting one of the most cost-effective manufacturing methods available. Manufacturers can save significantly on material procurement and energy bills, leading to lower overall production costs.

2. Scalability

Green sand casting is highly scalable, meaning it can be used for both small-scale and large-scale production. The process is flexible and can accommodate a wide range of production volumes, making it suitable for companies of all sizes. Whether producing a small batch of custom parts or mass-producing thousands of identical components, green sand casting can meet the demands of various industries.

3. Sustainability

As sustainability becomes increasingly important to consumers and businesses alike, green sand casting’s environmentally friendly nature is a significant advantage. The reduction of material waste, lower energy consumption, and minimal chemical waste all contribute to a greener manufacturing process. This aligns with global efforts to reduce the carbon footprint of industries and promote more sustainable practices.

Common Applications of Green Sand Casting

Green sand casting is widely used across various industries, including:

- Automotive: For casting engine blocks, cylinder heads, and other critical components.

- Aerospace: For manufacturing parts that require high durability and precision.

- Industrial Equipment: For producing machinery components, pumps, and valves.

- Construction: For casting structural components like beams and supports.

- Marine: For creating parts that withstand harsh environmental conditions.

Conclusion

Green sand casting offers numerous advantages in terms of reducing waste and improving efficiency in metal parts manufacturing. With its ability to reuse materials, minimize waste, and lower production costs, this method is both environmentally friendly and economically viable. The use of green sand casting helps manufacturers meet the growing demand for high-quality, sustainable products while also optimizing their operations. As industries continue to prioritize sustainability and efficiency, green sand casting is poised to remain a crucial process in the future of metal parts manufacturing.

FAQ

1. What are the main advantages of green sand casting over other methods?

Green sand casting offers lower material costs, reduced energy consumption, and minimal waste generation. It also allows for the reuse of materials, making it an environmentally friendly and cost-effective option.

2. Can green sand casting be used for all types of metals?

Yes, green sand casting is versatile and can be used to cast a wide range of metals, including iron, steel, aluminum, and other alloys.

3. Is green sand casting suitable for high-precision parts?

While green sand casting offers good dimensional accuracy, it may not be ideal for parts requiring extremely tight tolerances. For such applications, investment casting or die casting may be more appropriate.

4. How many times can green sand be reused?

Green sand can be reused multiple times, depending on the quality of reclamation processes. In many cases, sand can be recycled up to 10-20 times before it needs to be replaced.

5. What industries benefit the most from green sand casting?

Green sand casting is widely used in industries such as automotive, aerospace, industrial equipment manufacturing, and construction, thanks to its cost-effectiveness and versatility.

Stay Connected with Us

Thank you for reading! We hope this blog provided you with valuable insights and inspiration on acoustic panel ceilings. If you enjoyed the content and want to stay updated with the latest trends, tips, and behind-the-scenes updates, we’d love to connect with you on social media.

📘 Follow us on Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Join our growing community where we share expert advice, product highlights, and interactive discussions with professionals and design enthusiasts from around the world.

Let’s keep the conversation going—see you there!

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF