Investment Casting vs Sand Casting: 5 Differences Explained

When it comes to choosing the right casting process for a project, two of the most common methods are investment casting and sand casting. Both of these casting techniques have unique benefits and drawbacks depending on the complexity, material, and volume of parts being produced. In this article, we’ll dive into the key differences between investment casting and sand casting to help you make an informed decision on which process is right for your application.

Table of Contents

Introduction

Before we dive into the differences, let’s first define investment casting and sand casting. These are two of the most widely used casting methods in various industries such as aerospace, automotive, medical devices, and heavy equipment manufacturing.

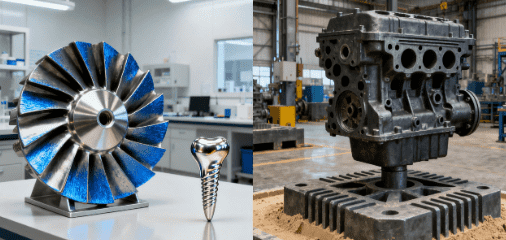

- Investment Casting: Also known as lost-wax casting, investment casting involves creating a precise mold using a wax pattern. This process is known for producing parts with high accuracy and fine surface finishes. The mold is made by coating the wax pattern in a ceramic shell, and once hardened, the wax is melted out, leaving behind a hollow mold for pouring molten metal.

- Sand Casting: Sand casting, on the other hand, uses sand to form the mold. The mold is created by packing sand around a pattern of the part to be cast, which is then removed, leaving behind a cavity that is filled with molten metal. Sand casting is a more cost-effective method for producing larger parts, but it does not offer the same level of detail or surface finish as investment casting.

In this article, we’ll explore five key differences between investment casting and sand casting, focusing on factors such as cost, accuracy, lead times, material compatibility, and applications.

Key Difference 1: Surface Finish and Dimensional Accuracy

Investment Casting vs Sand Casting: Which Provides Better Surface Finish?

One of the most significant distinctions between investment casting and sand casting is the surface finish and dimensional accuracy of the parts produced. These factors often play a crucial role in determining which casting method is most appropriate for a given application.

Investment Casting

The investment casting process, often referred to as lost-wax casting, results in parts with a smooth surface finish that typically requires minimal post-processing. The high-quality ceramic shell used to form the mold gives investment casting a significant advantage when it comes to surface quality. Because of this, investment casting is widely used for complex geometries, intricate designs, and components that demand fine details and high surface quality. Parts produced by this method generally require less finishing work than parts produced by sand casting, which helps save time and labor costs.

The precision of investment casting allows it to produce parts with smoother finishes that have significantly less visible texture, making it ideal for parts with exacting surface requirements, especially those used in industries like aerospace, medical devices, and electronics. The process’s ability to achieve high precision also means that it is capable of producing intricate micro-features that would otherwise be difficult to achieve with other casting methods.

Sand Casting

In contrast, sand casting tends to leave parts with a rougher surface finish, requiring additional post-casting processes such as machining, grinding, or shot blasting to meet required tolerances. The mold itself is made of compacted sand, which leads to a more textured surface. This roughness can introduce challenges, such as porosity (tiny holes or voids), which may affect the mechanical properties or the aesthetic appearance of the final part. While sand casting is sufficient for many industrial applications, it’s not generally suitable for parts requiring fine surface finishes without significant post-processing work.

Moreover, the surface finish can also be affected by the choice of sand used, the molding process, and the complexity of the design. Sand casting is a more viable option for parts where roughness is acceptable or where the parts are relatively simple and do not require high cosmetic quality.s.

Dimensional Accuracy Comparison

- Investment Casting typically offers superior dimensional accuracy, with parts produced to tolerances as tight as ±0.005 inches (0.13mm). This level of precision makes it ideal for applications that require complex geometries and parts with high-performance standards, such as those found in the aerospace and medical industries. Due to the high precision, investment casting can often eliminate the need for machining or other secondary processes.

- Sand Casting, by comparison, has more lenient tolerances, typically ranging from ±0.015 to ±0.050 inches (0.38mm to 1.27mm), depending on the size and complexity of the part. While this may be acceptable for many industrial components, sand casting falls short when it comes to parts that demand highly detailed and precise design specifications. For high-precision applications, investment casting is often the preferred choice due to its superior dimensional accuracy.

In general, if your project requires parts with fine surface finishes and tight tolerances, investment casting will likely be the better option. On the other hand, sand casting is a solid choice for applications where cost-efficiency is prioritized and surface finish and tolerances can be less critical.

Key Difference 2: Cost and Production Volume

Cost of Investment Casting vs Sand Casting

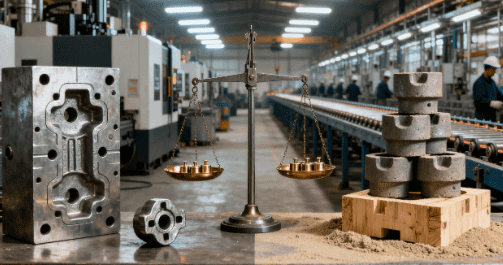

Cost is often one of the most important factors to consider when deciding between investment casting and sand casting. While investment casting is known for its precision and ability to handle complex designs, it is generally more expensive due to the nature of the process.

Investment Casting

The higher costs associated with investment casting stem from the creation of the molds. These molds are typically made from wax patterns that are coated in a ceramic shell, which is then fired to create the final mold. The labor-intensive nature of the process, combined with the high-quality materials required (such as ceramics and wax), makes investment casting more expensive. Additionally, the process requires multiple steps to complete, including wax injection, shell building, and wax removal, all of which contribute to the cost.

Investment casting is often more appropriate for small to medium production runs of high-precision parts, particularly when the requirements for detail and performance outweigh the importance of cost.

Sand Casting

In contrast, sand casting is far more cost-effective, especially for large parts or high-volume production runs. The molds are created using a relatively inexpensive material—sand—combined with a binder to help shape it. Because the materials are low-cost and the process is less labor-intensive, sand casting is typically more affordable. Moreover, sand casting molds can be reused multiple times, further reducing costs for high-volume production.

For larger parts or mass production, sand casting is usually the preferred method because it offers significant cost savings compared to investment casting. However, when high precision and fine detailing are required, investment casting will still be the go-to choice despite the higher cost.

Production Volume Considerations

- Investment Casting is ideal for low to medium production runs, especially when high precision is required. However, due to the higher tooling and labor costs, investment casting becomes less cost-effective for large-volume production.

- Sand Casting is well-suited for high-volume manufacturing, especially of larger parts that do not require the fine accuracy and high finish associated with investment casting. The cost-efficiency of sand casting makes it a top choice for applications like engine blocks, large housings, and heavy-duty components.

Key Difference 3: Material Options

Material Compatibility in Investment Casting vs Sand Casting

Both investment casting and sand casting offer a broad range of materials, but the material choices available for each process vary in terms of compatibility, cost, and performance characteristics.

Investment Casting

Investment casting allows for a broader selection of materials, including high-performance alloys and specialized metals. The process can accommodate materials such as stainless steel, aluminum, bronze, brass, and superalloys (such as titanium, nickel-based alloys, and cobalt-based alloys). These metals are ideal for applications that require high strength, resistance to corrosion, or the ability to perform under extreme conditions. The fine detailing achievable in investment casting makes it the go-to process for aerospace, medical, and automotive components that need specialized alloys with exacting properties.

Sand Casting

Sand casting also offers a wide range of material options, although it is generally more limited in terms of specialized alloys. It is most commonly used with ferrous and non-ferrous metals such as gray iron, aluminum, bronze, and brass. While it can also be used for steel alloys, it is generally not as suitable for higher-performance materials like superalloys. The process is better suited for cast iron and aluminum alloys, making it more suitable for large, simpler parts used in industries like construction, heavy machinery, and automotive.

| Material Type | Investment Casting | Sand Casting |

|---|---|---|

| Steel | Yes (including high-alloy steels) | Yes (standard carbon steel) |

| Aluminum | Yes | Yes |

| Bronze & Brass | Yes | Yes |

| Iron | Yes | Yes (including gray iron) |

| Titanium | Yes | Limited |

Key Difference 4: Lead Time and Turnaround

Investment Casting vs Sand Casting: Which Has a Shorter Lead Time?

When comparing the lead time and turnaround times of investment casting and sand casting, it’s essential to consider the different complexities involved in each process.

Investment Casting

Investment casting, while known for its precision, can have a longer lead time. This is primarily due to the intricate process of creating wax patterns, followed by coating them with a ceramic shell and allowing it to dry. The time required to produce these molds can be significant, especially for complex designs. The wax pattern creation process involves meticulous attention to detail to ensure that the final part matches the desired specifications.

However, once the molds are created, the casting process itself can be relatively quick. After the wax is melted out, the molten metal is poured into the mold, which is a much faster step. As a result, investment casting is generally preferred for low to medium production runs or prototyping when precision and detail are critical, despite the longer initial mold creation time.

Sand Casting

On the other hand, sand casting tends to have a shorter lead time compared to investment casting, primarily because of its simpler mold-making process. Sand molds are created by compacting sand around a pattern, which is much faster than the intricate mold-making process of investment casting. Additionally, sand molds can be reused, which further shortens lead times for repeat orders and high-volume productions.

Sand casting can often be completed more quickly for large parts or mass production runs, especially if the parts do not require highly detailed or complex features. It’s an excellent choice when fast turnaround is essential and when the focus is more on cost-effectiveness rather than precision.

In summary, if you are looking for fast lead times for large-volume production, sand casting is likely the better choice. However, if your project requires high precision and detailed designs, investment casting will require a longer lead time but ultimately provide superior results.

Key Difference 5: Application Suitability

Which Casting Process Is Right for Your Application?

When deciding between investment casting and sand casting, it’s essential to consider which process is best suited for the requirements of your specific application. Both casting methods have their strengths, but the decision depends on factors such as part complexity, volume, and performance needs.

Investment Casting

Investment casting is ideal for parts that require high precision, intricate designs, and tight tolerances. Its ability to produce complex geometries with detailed features makes it a top choice for industries that demand high-performance parts.

- Aerospace: For producing lightweight, high-strength components like turbine blades, investment casting ensures both precision and performance under extreme conditions.

- Automotive: When manufacturing components like engine blocks, valves, or turbochargers, investment casting is used for its ability to produce highly detailed and complex parts that require durability and strength.

- Medical Devices: The need for fine details, biocompatibility, and precision in components like surgical tools or prosthetics makes investment casting the go-to method.

- Energy: Critical components such as valves, seals, and turbines benefit from the superior precision and material versatility offered by investment casting.

Given the nature of these industries, investment casting is often the best choice when high performance and precision are required, particularly for low to medium volume runs of complex parts.

Sand Casting

While investment casting excels in precision, sand casting is typically more suited for larger, less complex parts. This casting method is ideal for parts where cost-efficiency is a top priority, and the parts don’t require the level of detail or precision that investment casting provides.

- Construction: Sand casting is widely used for producing large, simple components like manhole covers, construction machinery parts, and heavy-duty castings.

- Heavy Machinery: Components that require strength but don’t need fine surface finishes, such as engine blocks and gear housings, can be effectively manufactured using sand casting.

- Industrial Equipment: Parts that need to be both functional and cost-effective, like pumps, valves, and bearing housings, are often produced using sand casting because of its low material costs and efficiency for large production runs.

For industries where mass production and cost efficiency are more critical than fine detailing, sand casting offers a practical solution. This method is ideal for larger parts or high-volume production of simple geometries that do not require precision machining or tight tolerances.

Conclusion

In conclusion, both investment casting and sand casting have their place in the manufacturing world. The right choice depends on factors like material type, production volume, cost constraints, and the precision required for the part. Investment casting shines when high accuracy and detailed surface finishes are required, whereas sand casting remains the go-to method for large, simpler parts that prioritize cost-effectiveness.

By understanding the key differences between investment casting and sand casting, you can select the casting process that best meets the specific needs of your project, ensuring both quality and efficiency.

FAQ

1. Which process is better for large parts?

Sand casting is typically the better option for producing large parts. The sand molds can be easily scaled to accommodate bigger components, and the process is more cost-effective for mass production. Sand casting is often the go-to method for industries that require large, simple shapes in bulk.

2. Is investment casting suitable for high-volume production?

Investment casting is generally better suited for low to medium-volume production due to its higher cost. However, for specialized parts that require high precision and complex geometries, investment casting can be used effectively in high-volume applications where accuracy justifies the additional cost.

3. Can investment casting be used for intricate designs?

Yes, investment casting excels at producing intricate designs and parts with complex geometries. The precision of the process allows for the creation of fine details and tight tolerances, making it ideal for applications in industries like aerospace and medical devices.

4. Which process is better for prototyping?

Investment casting is often the preferred method for prototyping, especially when high accuracy and functional prototypes are needed quickly. The process allows for rapid creation of detailed and dimensionally accurate prototypes, enabling efficient testing and adjustments.

5. Can sand casting achieve tight tolerances?

Sand casting typically does not offer the same level of precision as investment casting and is best suited for parts with moderate tolerances. While it can still produce functional parts with reasonable accuracy, it generally requires additional finishing to meet tight tolerance specifications.

Stay Connected with Us

Thank you for reading! We hope this blog provided you with valuable insights and inspiration on acoustic panel ceilings. If you enjoyed the content and want to stay updated with the latest trends, tips, and behind-the-scenes updates, we’d love to connect with you on social media.

📘 Follow us on Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Join our growing community where we share expert advice, product highlights, and interactive discussions with professionals and design enthusiasts from around the world.

Let’s keep the conversation going—see you there!

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF