What is 1030 Carbon Steel? A Comprehensive Guide

Table of Contents

Introduction

1030 carbon steel is a high-carbon steel alloy, known for its moderate hardness and high strength, making it a versatile material for a wide range of industrial applications. With a carbon content of approximately 0.30%, it strikes a balance between the softness of low-carbon steels and the hardness and strength of medium-carbon steels. This balance makes 1030 steel particularly useful in applications where strength and hardness are required but without the brittleness that comes with higher-carbon steels.

In this comprehensive guide, we will explore what 1030 carbon steel is, its key properties, its applications in various industries, and its performance in casting and heat-treated conditions. Additionally, we will dive into the advantages and considerations of using 1030 steel in manufacturing processes.

What is 1030 Carbon Steel?

1030 carbon steel is a member of the SAE (Society of Automotive Engineers) steel grade classification system. It is categorized as a high-carbon steel, with a carbon content of around 0.30%, which makes it stronger and harder than low-carbon steels like 1018 but more machinable than higher-carbon steels such as 1045 or 1060. The relatively higher carbon content contributes to its strength, while maintaining enough ductility for forming and machining.

This steel alloy is widely used in applications requiring moderate strength and good wear resistance, especially when parts need to be hardened or tempered to improve mechanical properties.

The chemical composition of 1030 carbon steel typically includes:

- Carbon (C): 0.28% – 0.34%

- Manganese (Mn): 0.60% – 0.90%

- Phosphorus (P): 0.04% max

- Sulfur (S): 0.05% max

1030 carbon steel is used in applications that require strength, durability, and the ability to withstand moderate stress and wear.

Key Properties of 1030 Carbon Steel

Strength and Hardness

One of the defining characteristics of 1030 carbon steel is its high strength and moderate hardness. This is due to the higher carbon content compared to low-carbon steels. The tensile strength of 1030 steel typically ranges from 570 to 700 MPa (82,650 to 101,500 psi), depending on the heat treatment applied.

While 1030 steel offers greater strength than lower-carbon steels, its hardness is also moderate, making it ideal for parts that need strength without excessive brittleness. In its normal annealed state, the steel has a Brinell hardness rating of approximately 160-180 HB, but this can be increased through processes like quenching and tempering, which allow the steel to achieve higher levels of hardness for specific applications.

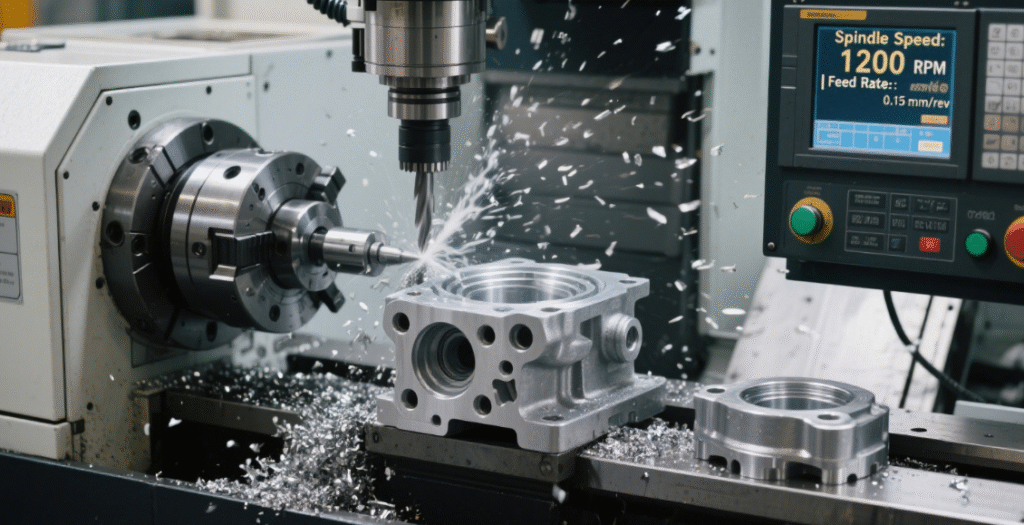

Machinability and Formability

1030 carbon steel is machinable and formable, though its higher carbon content makes it more challenging to work with compared to lower-carbon steels. It can be readily turned, drilled, milled, and ground to produce precision components. The steel maintains good formability, allowing it to be bent or shaped without significant cracking or deformation.

The material’s machinability, however, can be affected by its hardness and work-hardening tendency. For this reason, cutting speeds and tooling may need to be adjusted, particularly when machining hardened or heat-treated parts. But in general, 1030 steel is still easier to machine than higher-carbon steels, such as 1045.

Weldability

1030 carbon steel has good weldability when compared to higher-carbon steels, thanks to its moderate carbon content. It can be welded using conventional methods like MIG, TIG, and Stick welding, with appropriate preheating and post-weld heat treatment to avoid issues such as cracking.

However, welding 1030 carbon steel requires attention to the material’s heat sensitivity, especially when working with thicker sections. The heat from welding can induce stresses that could lead to cracking or distortion if not managed properly. In some cases, post-weld heat treatment may be required to relieve internal stresses and improve the overall strength of the welded joint.

Corrosion Resistance

While 1030 carbon steel is not inherently corrosion-resistant, it can be protected through various coating methods like galvanization or painting. These coatings help protect the material from the damaging effects of moisture, air, and other corrosive elements.

Without these protective coatings, 1030 steel will corrode over time when exposed to the elements, especially in environments with high humidity or salt content. In situations where corrosion resistance is critical, consider alloying the steel or using surface treatments like phosphating or electroplating.

Applications of 1030 Carbon Steel

1030 carbon steel is widely used in various industrial applications, particularly when moderate strength and machinability are important. Below are some of the most common uses:

Mechanical Parts

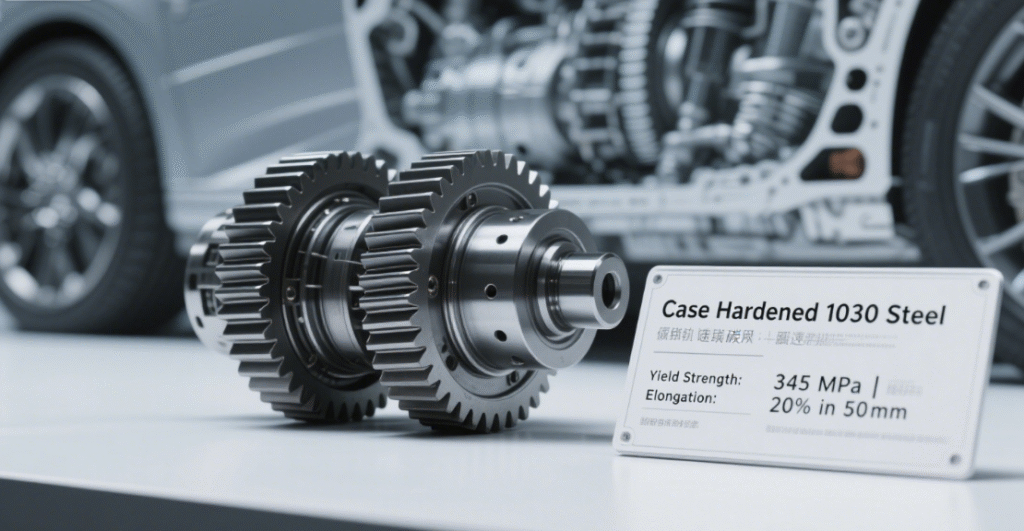

1030 steel is used in the production of mechanical parts that require moderate strength and wear resistance, such as gears, shafts, and spindles. Its ability to be hardened and tempered makes it particularly useful for parts that need to maintain a balance between toughness and durability under moderate load conditions.

Automotive Components

In the automotive industry, 1030 carbon steel is used for manufacturing various components like axles, brake shafts, and steering linkages. These parts require a combination of high strength, wear resistance, and machinability, which makes 1030 an excellent choice for these applications.

Tooling and Dies

Due to its ability to be heat-treated to increase hardness, 1030 steel is also used in the production of tools and dies. 1030 carbon steel is commonly used for making components like cutting tools, molds, and die inserts. These tools require a good combination of hardness for wear resistance and toughness to withstand the stresses of daily operation.

Structural Components

1030 steel is also used in structural applications, such as making frames, brackets, and supports. The steel’s moderate strength makes it suitable for parts that are not exposed to excessive loads or wear but still require durability and ease of machining.

1030 Carbon Steel in the Casting Industry

In the casting industry, 1030 carbon steel is commonly used for casting components that require moderate strength and hardness. It can be cast into various forms using techniques like sand casting or investment casting. After casting, 1030 steel is typically heat-treated to enhance its properties, improving the final component’s strength, wear resistance, and overall performance.

Some casting applications of 1030 carbon steel include:

- Pump components: Such as pump shafts and impellers, which require strength and wear resistance.

- Machine parts: Like gears, sprockets, and bearings that must endure moderate stress.

- Automotive castings: Used in engine components and brackets.

The heat treatment of 1030 steel can further enhance its mechanical properties by quenching and tempering, making it well-suited for high-performance casting applications.

Table: Key Properties and Applications of 1030 Carbon Steel

| Property | Details |

|---|---|

| Carbon Content | 0.28% – 0.34% |

| Tensile Strength | 570 – 700 MPa (82,650 – 101,500 psi) |

| Hardness | 160 – 180 HB |

| Machinability | Good, though harder than low-carbon steels |

| Weldability | Good, requires proper heat control |

| Corrosion Resistance | Moderate, requires coatings or treatments |

| Applications | Mechanical parts, automotive components, tooling, structural parts |

| Casting Suitability | Suitable for sand and investment casting |

Advantages of 1030 Carbon Steel

- Strength and Durability: 1030 steel provides good strength and moderate hardness, making it suitable for a wide range of applications.

- Machinability: The steel can be easily machined to create parts with precise tolerances, contributing to reduced manufacturing costs.

- Weldability: It offers good weldability, especially compared to higher-carbon steels, which can be more difficult to weld.

- Heat Treatability: 1030 steel can be hardened and tempered to increase strength and wear resistance, providing versatility for different applications.

Conclusion

1030 carbon steel is a versatile, high-carbon steel alloy that offers a combination of strength, machinability, and heat treatability, making it ideal for a wide range of industrial applications. While it is not as hard as other higher-carbon steels, its moderate hardness and excellent weldability make it a go-to choice for parts that require durability, strength, and ease of fabrication. Whether you are manufacturing gears, shafts, or tooling, 1030 steel provides a reliable and cost-effective solution for your needs.

FAQ

What is the difference between 1030 and 1045 carbon steel?

The main difference between 1030 and 1045 carbon steel is the carbon content. 1045 contains 0.45% carbon, making it stronger and harder than 1030, but also more difficult to machine and weld. 1030 steel offers moderate strength and is easier to work with, making it ideal for applications that don’t require the extreme hardness of 1045.

Can 1030 carbon steel be heat treated?

Yes, 1030 steel can be heat-treated to increase its hardness and strength. It can be quenched and tempered to improve its mechanical properties, especially for high-stress applications.

Is 1030 carbon steel resistant to corrosion?

No, 1030 carbon steel is not naturally corrosion-resistant. It can rust if exposed to moisture and air. Protective coatings like galvanization, painting, or powder coating are recommended for corrosion resistance.

What industries use 1030 carbon steel?

1030 carbon steel is used across various industries, including automotive, construction, machinery, and tool manufacturing. It is often found in mechanical parts, automotive components, tools, and structural applications.

Stay Connected with Us

Thank you for reading! We hope this blog provided you with valuable insights and inspiration on acoustic panel ceilings. If you enjoyed the content and want to stay updated with the latest trends, tips, and behind-the-scenes updates, we’d love to connect with you on social media.

📘 Follow us on Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Join our growing community where we share expert advice, product highlights, and interactive discussions with professionals and design enthusiasts from around the world.

Let’s keep the conversation going—see you there!

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF