3 Astonishing Advantages of Steel Casting Impellers in Pumps

Welcome to My Blog!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

Table of Contents

Introduction

In the world of fluid – handling systems, pumps play a crucial role. The performance of a pump is highly dependent on its components, and one of the most vital parts is the impeller. Among various types of impellers, steel casting impellers have emerged as a remarkable choice. This blog will explore three astonishing advantages of using steel casting impellers in pumps, shedding light on why they are becoming increasingly popular in different industries.

Understanding Steel Casting Impellers

What is a Steel Casting Impeller?

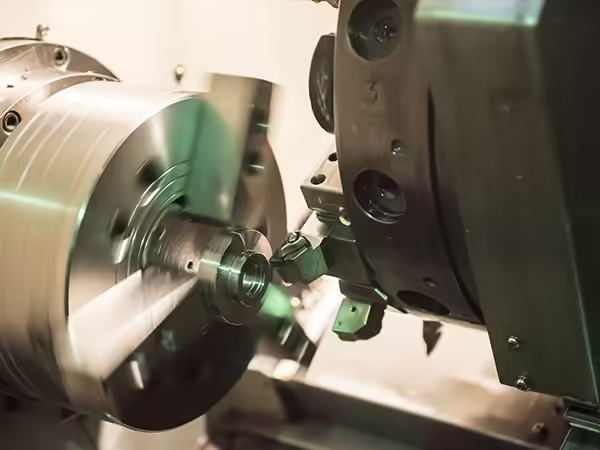

A steel casting impeller is a component of a pump that is manufactured through the casting process using steel as the base material. Casting involves pouring molten steel into a mold of the desired impeller shape and allowing it to solidify. This process enables the creation of complex geometries with high precision.

Manufacturing Process

The manufacturing of a steel casting impeller starts with the design of the mold. The mold is typically made of sand or other refractory materials. Once the mold is ready, molten steel is prepared in a furnace. The molten steel is then poured into the mold under controlled conditions to ensure proper filling and solidification. After the steel has cooled and solidified, the impeller is removed from the mold and undergoes finishing processes such as machining, grinding, and surface treatment to achieve the required dimensions and surface quality.

Advantage 1: High Strength and Durability

Explanation of Strength and Durability

One of the most significant advantages of steel casting impellers is their high strength and durability. Steel is a material known for its excellent mechanical properties, including high tensile strength, yield strength, and hardness. In a pump, the impeller is subjected to high – speed rotation, fluid forces, and sometimes abrasive particles in the fluid. A steel casting impeller can withstand these harsh conditions without significant deformation or wear.

Benefits in Pump Performance

The high strength and durability of a steel casting impeller contribute to the long – term performance of the pump. It reduces the risk of impeller failure, which can lead to pump breakdowns and costly repairs. For example, in industrial pumps used in mining or chemical processing, where the fluid may contain abrasive particles, a steel casting impeller can maintain its shape and performance for a longer time compared to impellers made of other materials. This results in increased pump reliability and reduced downtime.

Advantage 2: Excellent Corrosion Resistance

Mechanisms of Corrosion Resistance

Steel casting impellers can be designed to have excellent corrosion resistance. This is achieved through the selection of appropriate steel alloys and surface treatments. Some steel alloys contain elements such as chromium, nickel, and molybdenum, which form a passive oxide layer on the surface of the impeller. This oxide layer acts as a barrier, preventing the steel from reacting with corrosive substances in the fluid. Additionally, surface treatments such as coating or plating can further enhance the corrosion resistance of the impeller.

Impact on Pump Lifespan

The excellent corrosion resistance of a steel casting impeller has a significant impact on the pump’s lifespan. In applications where the pumped fluid is corrosive, such as in the chemical industry or marine environments, a corrosion – resistant impeller can prevent the pump from being damaged by corrosion. This extends the service life of the pump and reduces the need for frequent impeller replacement, saving both time and money.

Advantage 3: Customizability

Design Flexibility

Steel casting impellers offer a high degree of design flexibility. The casting process allows for the creation of impellers with complex shapes and geometries. This is important because different pump applications require impellers with specific designs to optimize pump performance. For example, in a centrifugal pump, the impeller design can be tailored to achieve the desired flow rate, head, and efficiency.

Adaptability to Different Applications

The customizability of steel casting impellers makes them adaptable to a wide range of applications. Whether it is a small – scale domestic pump or a large – scale industrial pump, a steel casting impeller can be designed to meet the specific requirements of the application. This includes considerations such as the type of fluid being pumped, the operating conditions, and the performance goals of the pump.

Comparison Table: Steel Casting Impellers vs Other Impeller Materials

| Material | Strength and Durability | Corrosion Resistance | Customizability | Cost |

|---|---|---|---|---|

| Steel Casting Impellers | High | Excellent (with proper alloy and treatment) | High | Medium – High |

| Aluminum Impellers | Medium | Good (but lower than steel in some cases) | Medium | Low – Medium |

| Plastic Impellers | Low | Good in some non – corrosive fluids | Medium | Low |

Conclusion

In conclusion, steel casting impellers offer three astonishing advantages in pumps: high strength and durability, excellent corrosion resistance, and customizability. These advantages make them a preferred choice for a wide range of pump applications, from small – scale domestic use to large – scale industrial operations. By understanding and utilizing these advantages, the pump industry can achieve more efficient, reliable, and long – lasting pump solutions.

FAQ

Q1: Can steel casting impellers be used in high – temperature applications?

A: Yes, steel casting impellers can be used in high – temperature applications. However, the choice of steel alloy is crucial. Some high – temperature steel alloys are specifically designed to maintain their mechanical properties at elevated temperatures. It is important to consult with a materials expert or the impeller manufacturer to select the appropriate alloy for high – temperature use.

Q2: How do I maintain a steel casting impeller?

A: Maintenance of a steel casting impeller mainly involves regular inspection for signs of wear, corrosion, or damage. If the impeller is exposed to abrasive fluids, it may be necessary to clean it periodically to remove any accumulated debris. Additionally, if the impeller has a surface coating or treatment, it should be checked for integrity and re – applied if necessary.

Q3: Are steel casting impellers more expensive than other types of impellers?

A: Generally, steel casting impellers may have a higher initial cost compared to some other types of impellers such as plastic impellers. However, considering their long – term durability, corrosion resistance, and customizability, they can provide better value for money in the long run. The cost – effectiveness also depends on the specific application and the expected service life of the impeller.

Q4: Can steel casting impellers be repaired if damaged?

A: In some cases, steel casting impellers can be repaired if they are damaged. Minor damage such as small cracks or surface wear can be repaired through processes such as welding, machining, or surface restoration. However, for severe damage, it may be more cost – effective to replace the impeller.

Q5: How can I ensure the quality of a steel casting impeller?

A: To ensure the quality of a steel casting impeller, it is important to purchase from a reputable manufacturer. The manufacturer should have a quality control system in place, including material testing, dimensional inspection, and non – destructive testing. It is also advisable to ask for product certifications and test reports to verify the quality of the impeller.

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF