9 Massive Changes in 3D Printed Cast: Leading Industry Trend

Table of Contents

Introduction

The manufacturing landscape is in constant evolution, driven by technological advancements that reshape traditional processes and open new frontiers for production. Among these transformative innovations, the integration of 3D printing with casting methods, often referred to as 3D printed cast, stands out as a pivotal development. This convergence of additive manufacturing and age-old casting techniques is not merely an incremental improvement; it represents a fundamental shift in how complex metal components are designed, prototyped, and mass-produced. From rapid prototyping to enhanced material customization and unparalleled design freedom, the influence of 3D printing on casting is creating a new era of efficiency, precision, and innovation across various industries.

This blog post will delve into nine significant ways that 3D printed cast technologies are redefining manufacturing, highlighting their immense potential to lead new industry trends.

The Rise of 3D Printed Cast Technology

For centuries, casting has been a cornerstone of manufacturing, enabling the creation of intricate metal parts essential for industries ranging from automotive to aerospace. However, traditional casting often involves lengthy lead times, high tooling costs, and limitations in design complexity. The advent of 3D printing technology has provided a revolutionary answer to many of these challenges. By leveraging industrial 3D printing solutions, manufacturers can now overcome previous constraints, introducing unprecedented flexibility and speed into the casting process.

The integration of 3D printing technology into metal casting, broadly termed 3D printed cast, refers to various applications where additive manufacturing plays a crucial role. This can include 3D printing patterns for sand casting or investment casting, or even directly 3D printing molds and cores, thereby significantly streamlining the entire production cycle and enabling the creation of components that were previously impossible to achieve with conventional methods. This technological synergy is fostering a new era of efficient production and injecting innovative momentum into the manufacturing field globally.

9 Massive Changes in 3D Printed Cast: Leading New Industry Trends

The impact of 3D printed cast is multifaceted, influencing various stages of the manufacturing process and offering distinct advantages that redefine industry standards. Here are nine key changes:

1. Enhanced Customization and Flexibility with 3D Printed Cast

One of the most profound impacts of adopting 3D printing solutions in casting is the unparalleled degree of customization and flexibility it offers. Traditional casting methods often require expensive and time-consuming tooling, making single-piece or small-batch production economically unfeasible. However, with 3D printed cast approaches, companies can efficiently cater to single-piece, small-batch, and even large-scale production requirements through flexible customization. This adaptability is crucial for industries that demand highly specialized components or frequently updated designs, allowing manufacturers to quickly pivot and meet diverse needs without significant upfront investment in molds or patterns. This flexible production model is a game-changer for businesses seeking to offer highly tailored products.

2. Speeding Up Prototyping and Production with 3D Printed Cast

The integration of 3D printing into casting significantly accelerates the entire product development lifecycle, from concept to final part. Known for its rapid prototyping capabilities, additive manufacturing can quickly produce patterns or molds for casting, drastically reducing the lead times associated with traditional methods. For instance, rapid prototyping via sand casting can take as little as 7-10 days, while silica sol casting might require 20-30 days, which are still remarkably faster than conventional tooling processes.

This rapid casting ability allows for quicker design iterations, faster testing, and ultimately, a much faster time-to-market for new products, injecting innovative momentum into the manufacturing field. Manufacturers can complete designs and produce samples within 3-5 weeks, depending on part complexity, before moving to mass production.

3. Material Versatility in 3D Printed Cast Applications

While traditional casting is known for its ability to work with various metals, the strategic application of 3D printing technology expands the possibilities for material application and optimization in sophisticated ways. Companies engaged in 3D printing solutions for casting can offer expertise across a wide range of alloy grades, enabling customers to select ideal materials to optimize their products for demanding global application requirements.

Common materials used in precision casting services that can benefit from 3D printing patterns or molds include stainless steel castings, carbon steel castings, and alloy steel castings. This comprehensive range of materials allows for the production of components with specific mechanical properties, corrosion resistance, and performance characteristics tailored to the exact needs of the end application.

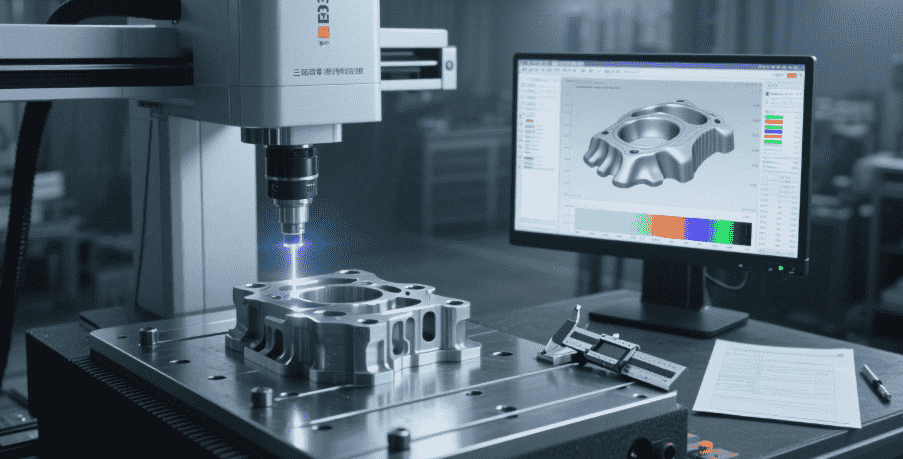

4. Precision and Quality Control in 3D Printed Cast Manufacturing

The demands for high-quality and high-precision metal parts have never been greater, and 3D printed cast techniques are instrumental in meeting these stringent requirements. By utilizing 3D printing to create highly accurate patterns or molds, the precision of the final cast part can be significantly enhanced. This technology allows for the replication of complex geometries with exceptional fidelity, leading to tighter tolerances and superior surface finishes.

Furthermore, manufacturers committed to these advanced methods typically implement comprehensive quality control systems, covering every step from raw material procurement to machining processes and final inspection. Certifications like ISO 9001:2015 and IATF 16949:2016 underscore a commitment to maintaining rigorous standards, ensuring the reliability and optimal performance of projects, especially for critical components in industries like automotive.

5. Integrated Solutions and End-to-End Support for 3D Printed Cast Projects

A key trend driven by the advancements in 3D printed cast technology is the move towards integrated manufacturing solutions and end-to-end support for clients. Instead of merely providing individual casting services, leading manufacturers offer a full spectrum of capabilities, solving production problems with less effort and worry. This includes comprehensive support from initial design evaluation (based on CAD drawings and 3D files) through cost calculation, material preparation, production, and final delivery.

Such integrated services, which often combine precision casting, investment casting, sand casting, CNC machining, and industrial 3D printing, provide a one-stop service from design to finished product. This holistic approach ensures seamless project execution and allows customers to focus on their core competencies while relying on expert partners for their metal part manufacturing needs.

6. Global Reach and Service Network for 3D Printed Cast Products

The adoption of advanced manufacturing techniques, including those associated with 3D printed cast, facilitates a broader global market reach and the establishment of robust international service networks. Companies deeply engaged in 3D printing solutions often leverage their technological leadership and flexible production models to distribute products to numerous regions worldwide. This global layout capability, built on rich export experience, helps products expand into international markets and meet diverse customer needs across continents. Supporting global shipping for every order, manufacturers can serve clients from North America, South America, Asia, and Europe, building long-term cooperation and strong relationships by providing exceptional customer service and high-quality cast products.

7. Addressing Industry-Specific Needs with 3D Printed Cast

The versatility of 3D printed cast solutions allows manufacturers to tailor their offerings to the specific, stringent requirements of various industries. For instance, in Automobile Manufacturing, these processes meet the industry’s demanding requirements for component performance, consistency, and quality control, enabling the production of key parts like engine mounts and brake system components using alloy steel and carbon steel. In Valve Casting, advanced technologies like mold casting and silica sol processing, enhanced by 3D printing for complex patterns, achieve high-precision molding for complex structural parts that withstand high-temperature, high-pressure, and corrosion-resistant operating conditions.

Pump Manufacturing also benefits significantly, as pump products typically require high casting precision and specific material properties, with 3D printing solutions aiding in controlling uniformity of wall thickness and internal cavity accuracy for components like pump bodies and impellers. Even General Casting for construction machinery, marine components, or other non-specific metal components benefits from customized casting and machining services.

8. Cost Efficiency and Sample Provision for 3D Printed Cast Projects

While initially, the perception might be that advanced technologies like 3D printed cast are more expensive, they often lead to significant cost efficiencies, especially in the long run. By reducing the need for traditional tooling, minimizing material waste, and accelerating production timelines, overall project costs can be optimized. Furthermore, to instill confidence and ensure client satisfaction, many service providers offer a crucial advantage: one free sample for testing and approval before mass production begins.

This commitment to providing a qualified sample free of charge, with replacements if requirements are not met, mitigates risks for customers and underscores a dedication to quality and partnership. This practice is a testament to the reliability and confidence in the precision casting process integrated with 3D printing solutions.

9. Commitment to Innovation and Technological Leadership in 3D Printed Cast

The continuous evolution of manufacturing is driven by a strong commitment to innovation and technological leadership. Companies that are at the forefront of 3D printed cast are deeply engaged in exploring and implementing cutting-edge technology reserves and global professional resources. This dedication to mastering advanced 3D printing technology ensures that they remain competitive and can consistently inject innovative momentum into the production field. By staying abreast of the latest advancements in additive manufacturing and integrating them seamlessly with their casting expertise, these leaders are not just adapting to industry trends but actively shaping them, ensuring that their solutions remain at the cutting edge for efficient production.

Where Can I Get a 3d Printed Cast

If you are looking for a reliable partner to fulfill your 3D printed cast needs, Shanghai Leierwo Industry & Trade Co., Ltd. positions itself as a global manufacturer specializing in intelligent manufacturing, metal casting, industrial 3D printing, and rapid casting. They are deeply engaged in 3D printing solutions, offering end-to-end full-chain support, cutting-edge technology reserves, and global professional resources to inject innovative momentum into manufacturing.

Leierwo provides high-quality precision metal parts manufacturing services, including precision casting, investment casting, sand casting, and CNC machining, with 3D printing explicitly listed as one of their casting services. They offer customized solutions, capable of completing designs within 3–5 weeks depending on part complexity, and provide one free sample for testing before mass production.

Their expertise extends across a wide range of alloy grades, including stainless steel, carbon steel, and alloy steel castings, allowing customers to select optimal materials. Leierwo boasts over 18 years of experience in the precision casting and metal casting industry, holding ISO 9001:2015 and IATF 16949:2016 certifications for strict inspection procedures.

To start a project with Leierwo, you would typically follow these steps:

1. Submit Your Inquiry: Send CAD drawings and 3D files via email, specifying material grade, order quantity, surface finish, and other relevant details.

2. Cost Calculation: Their engineering team evaluates drawings and calculates prices based on actual production costs.

3. Start Production: Upon pricing approval, the production team prepares materials and schedules production, ensuring on-time delivery.

4. Arrange Delivery: After production, packaging details are provided, and shipment is arranged via sea or air, with global shipping supported.

Their integrated services and flexible production model can meet diverse needs, from single-piece to large-scale production, and they serve clients across North America, South America, Asia, and Europe.

| Feature / Service Category | Description | Benefits for 3D Printed Cast Projects |

| Industrial 3D Printing Solutions | Deep engagement in industrial 3D printing, mastering advanced 3D printing technology, and integrating it into casting processes. | Enables rapid prototyping, creation of complex geometries for patterns/molds, and innovative design freedom, speeding up the production cycle for various components. |

| Casting Services Offered | Comprehensive services including precision casting, investment casting, sand casting, and CNC machining, with 3D printing as a listed casting service. | Provides a full range of metal part manufacturing options, ensuring the most suitable and efficient method is chosen, often enhanced by 3D printing for improved precision and speed. |

| Material Expertise | Extensive knowledge across various alloy grades, including Stainless Steel Castings, Carbon Steel Castings, and Alloy Steel Castings. | Allows for optimal material selection to meet demanding application requirements, ensuring components possess desired mechanical properties and resistance characteristics for 3D printed cast parts. |

| Quality Control & Certifications | Adherence to ISO 9001:2015 and IATF 16949:2016 standards with strict inspection procedures at every stage, from raw materials to final inspection. | Guarantees high-performance and high-precision customized solutions, ensuring the reliability and optimal performance of all 3D printed cast components, especially in critical applications like automotive. |

| Flexible Production Model | Capable of flexible customization to meet needs for single-piece, small-batch, and large-scale production. | Offers agility in manufacturing, making it cost-effective for unique, specialized, or low-volume 3D printed cast components, as well as scalable solutions for larger orders without compromising efficiency. |

| Lead Times & Samples | Rapid prototyping (Sand casting: 7-10 days, Silica sol casting: 20-30 days); Mass production (45-60 days with machining); One free sample for testing and approval before mass production. | Accelerates product development and reduces risk by allowing customers to verify structure and quality with a free sample, ensuring the final 3D printed cast product meets specifications promptly. |

| Global Service Network | Products distributed to over 30 regions worldwide, serving customers across North America, South America, Asia, and Europe, with global shipping support. | Ensures accessibility and efficient delivery of 3D printed cast components to an international clientele, supported by extensive global export experience and a reliable service network. |

Conclusion

The integration of 3D printing with traditional casting, forming what we refer to as 3D printed cast, is undeniably at the forefront of modern manufacturing innovation. This powerful synergy is delivering transformative changes across the industry, offering unprecedented customization, accelerating production timelines, and enabling the use of diverse materials with enhanced precision. From offering integrated, end-to-end solutions to establishing a global service network and addressing highly specific industry needs, 3D printed cast technologies are redefining what is possible in metal parts manufacturing.

As manufacturers continue to leverage the advanced capabilities of industrial 3D printing within their casting operations, we can expect to see even greater efficiencies, more complex designs, and superior quality components, truly ushering in a new era of efficient production and pushing the boundaries of what industries can achieve. This ongoing evolution ensures that the future of manufacturing will be both more agile and more precise, driven by these groundbreaking innovations.

FAQ

Q1. Are you a trading company or a manufacturer?

We are a factory with over 20 years of experience in casting and machining, possessing rich expertise in this industry. If you encounter suppliers claiming to produce castings in a wide range of materials (such as steel, iron, stainless steel, copper, etc.), they are likely trading companies. If you observe workshops actively producing parts, you can be assured that we are a genuine manufacturer.

Q2. Can you quote based on 3D drawings for 3D printed cast projects?

Yes, we can provide a quotation as long as we receive CAD files or compatible 3D models that can be viewed with software like First Quote or Firstcut browser. We support 3D CAD models from SolidWorks (.sldprt), ProE (.prt), and other CAD systems, commonly in IGES (.igs), STEP (.stp), ACIS (.sat), or Parasolid (.sat) formats. Please note that 2D drawings alone are insufficient for manufacturing precision components.

Q3. What is your typical lead time for 3D printed cast projects?

For rapid prototyping, the lead time for silica sol casting is 20–30 days, and for sand casting, it is 7–10 days. For mass production that includes machining, the typical lead time is 45–60 days. More complex parts may require a different delivery schedule.

Q4. Do you provide samples for 3D printed cast components? Are they free?

Yes, we provide samples based on your drawings for you to confirm the structure and quality. If the sample does not meet your requirements, we will replace it free of charge until it is qualified.

Q5. How do you ensure quality control for 3D printed cast parts?

We have a comprehensive quality control system that covers every step, from raw material procurement to machining processes and final inspection. For critical components, we strictly follow drawing standards and customer specifications. All customer data is kept confidential, and only trained engineers are authorized to handle production orders. Third-party inspection or factory audits are welcome, or you may utilize our in-house quality team for final inspection.

Stay Connected with Us

Thank you for reading! We hope this blog provided you with valuable insights and inspiration on acoustic panel ceilings. If you enjoyed the content and want to stay updated with the latest trends, tips, and behind-the-scenes updates, we’d love to connect with you on social media.

📘 Follow us on Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Join our growing community where we share expert advice, product highlights, and interactive discussions with professionals and design enthusiasts from around the world.

Let’s keep the conversation going—see you there!

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF