4 Essential Strategies for Stainless Steel Investment Casting

Welcome to My Blog!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

Table of Contents

Introduction

Stainless Steel Investment Casting is a high-precision, versatile metalworking technique widely used in aerospace, automotive, medical devices, chemical processing, and industrial machinery. Understanding stainless steel investment casting processes helps manufacturers produce complex components with superior surface finish, tight tolerances, and long-term durability.

Modern industry demands components that can withstand extreme conditions without compromising precision. According to the 2023 International Foundry Association report, 30–40% of casting failures are caused by poor material selection or process control. Implementing effective strategies in stainless steel investment casting is essential to avoid defects, reduce rework, and save costs over the product lifecycle.

Key Takeaways

- How to select optimal stainless steel grades for investment casting

- Techniques to improve mold accuracy and surface finish

- Thermal management strategies to reduce casting defects

- Post-casting treatments and quality assurance for durability

- Comparative insights versus sand casting and die casting

- Industry-specific applications and performance benchmarks

Selecting the Right Stainless Steel Grade for Investment Casting

Understanding Material Properties

The first step in successful stainless steel investment casting is choosing the appropriate stainless steel grade. Each grade has unique properties affecting corrosion resistance, tensile strength, ductility, and thermal behavior. Selecting the correct grade ensures that components meet both functional and environmental requirements.

Common Stainless Steel Grades for Investment Casting

- 304 Stainless Steel: Excellent corrosion resistance in mild chemical environments, widely used in food processing and industrial equipment.

- 316 Stainless Steel: Superior resistance to chlorides and marine environments, ideal for chemical and pharmaceutical applications.

- 17-4 PH Stainless Steel: High strength and hardness, suitable for aerospace, high-load mechanical components, and tooling applications.

- 410 Stainless Steel: Hard, wear-resistant, often used for valves, fasteners, and machinery components.

Key Considerations in Grade Selection

- Environmental exposure (corrosive chemicals, humidity, high temperatures)

- Required mechanical performance (tensile, yield strength, impact resistance)

- Surface finish requirements and post-casting treatments

- Regulatory standards for specific industries (FDA, ASTM, ISO)

Expert Insight

Dr. Helen Carter, metallurgical engineer at FoundryTech, emphasizes:

“Selecting the right stainless steel grade at the design stage is the most critical decision. A mismatch can result in early failure or unnecessary overengineering.”

Optimizing Mold Design and Shell Preparation

The Importance of Mold Accuracy

Mold design is critical in stainless steel investment casting, impacting dimensional accuracy, surface quality, and defect rates. The Importance of Mold Accuracy in Stainless Steel Investment Casting

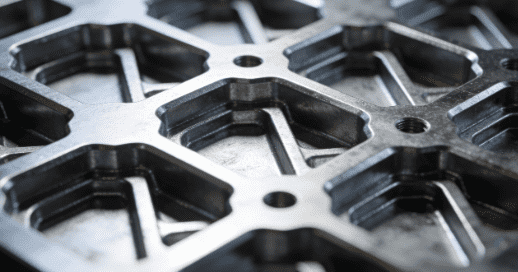

Mold design is a cornerstone of successful Stainless Steel Investment Casting. High-precision molds ensure dimensional accuracy, surface quality, and minimal defect rates. Wax patterns must replicate the exact geometry of the final component, and ceramic shells must endure thermal and mechanical stresses from molten stainless steel.

Inaccurate molds or improperly prepared shells can lead to shrinkage, warping, surface defects, and incomplete filling—all of which compromise the performance and longevity of Stainless Steel Investment Casting components.

Best Practices for Mold Design

To maximize the quality of Stainless Steel Investment Casting, consider the following practices:

- Create wax patterns with precise functional tolerances to match engineering specifications.

- Apply multiple layers of ceramic slurry to strengthen the mold shell and prevent cracking during pouring.

- Control drying and firing temperatures carefully to avoid thermal stress, warping, or shell cracking.

- Design proper gating and riser systems to ensure smooth metal flow and minimize turbulence.

- Implement vacuum or pressure-assisted shell preparation for high-precision stainless steel components.

Common Defects Linked to Mold Issues

Even minor mold inaccuracies can cause significant defects in Stainless Steel Investment Casting:

- Porosity due to trapped air or gases during pouring.

- Surface roughness from inconsistent ceramic shell application.

- Shrinkage or warping from uneven heating or thermal gradients.

- Incomplete filling in complex geometries, particularly thin walls or intricate internal features.

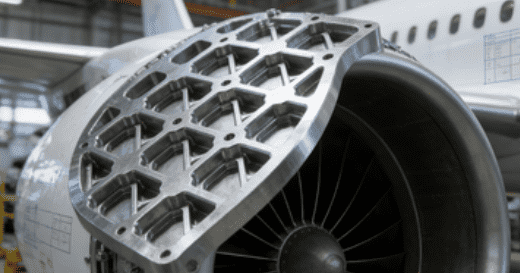

Case Study: Aerospace Application

A European aerospace foundry implemented optimized shell layering, controlled drying protocols, and precise wax pattern alignment for critical stainless steel components. After these improvements, scrap rates dropped by 22%, and the dimensional accuracy of Stainless Steel Investment Casting parts increased significantly.

According to the foundry’s lead engineer:

“Investing in mold preparation and precise shell management directly translates into fewer defects and higher overall efficiency in stainless steel investment casting.”

Managing Thermal and Pouring Conditions

Thermal Considerations

Thermal control is one of the most crucial factors in Stainless Steel Investment Casting. Molten stainless steel has a high melting point and significant fluidity, requiring careful temperature management to prevent common defects such as cold shuts, porosity, and hot tearing.

Key Thermal Practices:

- Maintain optimal pouring temperatures for each stainless steel grade (e.g., 1400–1500°C for 316 stainless steel).

- Preheat molds to reduce thermal shock and ensure smooth metal flow.

- Implement controlled cooling rates to minimize internal stresses, microcracks, and distortion.

- Monitor temperature gradients with thermocouples or infrared sensors to maintain uniform solidification.

Data Insight

A 2021 study published in the Journal of Materials Processing found that controlled thermal management reduced porosity defects in Stainless Steel Investment Casting by 28% compared with conventional pouring methods.

Expert Tip

John Miller, senior engineer at Global Foundry Solutions, explains:

“Precise thermal control and mold preheating are often overlooked. Most common defects in stainless steel investment casting, such as cold shuts and shrinkage, can be prevented by maintaining correct pouring and cooling temperatures.”

Advanced Pouring Techniques

For high-value Stainless Steel Investment Casting components:

- Vacuum-assisted pouring reduces air entrapment and minimizes porosity.

- Tilt pouring ensures uniform metal flow in complex molds.

- Automated pouring systems allow consistent temperatures and flow rates, reducing operator error.

Post-Casting Treatments and Quality Assurance

Heat Treatment for Performance Enhancement

Post-casting treatments in Stainless Steel Investment Casting improve mechanical performance, corrosion resistance, and durability:

- Annealing: Relieves internal stress, improves machinability (304, 316 stainless steel).

- Solution Treatment: Enhances corrosion resistance for food, medical, or chemical applications.

- Aging: Increases strength for precipitation-hardened grades like 17-4 PH stainless steel.

Surface Finishing Techniques

- Sandblasting or polishing improves surface smoothness and aesthetics.

- Electropolishing enhances corrosion resistance and reduces bacterial adhesion in hygienic applications.

- Deburring ensures assembly safety and dimensional precision.

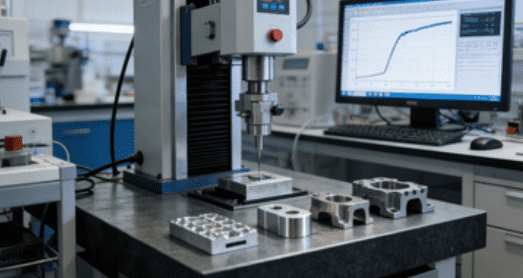

Nondestructive Testing (NDT)

- X-ray inspection detects internal voids or inclusions.

- Ultrasonic testing verifies internal structure integrity.

- Dye penetrant testing identifies surface cracks or porosity.

Table: Recommended Post-Casting Treatments

| Treatment Type | Purpose | Applicable Grades |

|---|---|---|

| Annealing | Stress relief, machinability | 304, 316 |

| Solution Treatment | Corrosion resistance | 304, 316 |

| Aging | Strength enhancement | 17-4 PH |

| Polishing | Surface finish improvement | All grades |

| Passivation | Corrosion protection | 304, 316 |

Comparing Stainless Steel Investment Casting to Other Methods

Concept: Why Investment Casting Stands Out

Investment casting offers superior precision, excellent surface finish, and the ability to produce intricate geometries, compared with sand casting or die casting.

Comparison Table: Casting Methods

| Feature | Investment Casting | Sand Casting | Die Casting |

|---|---|---|---|

| Dimensional Accuracy | High | Medium | High |

| Surface Finish | Smooth | Rough | Smooth |

| Complexity of Parts | Complex geometries | Simple | Moderate |

| Material Waste | Low | Medium | Medium-High |

| Cost per Part | Higher | Low | Medium |

Investment casting is preferred for aerospace, medical devices, and chemical components due to high precision requirements, despite higher initial costs.

Industry-Specific Applications and Insights

Aerospace: 17-4 PH stainless steel parts for high-strength components.

Medical: 316 stainless steel for surgical instruments and implants.

Chemical Industry: 316 and 304 stainless steel for corrosion-resistant valves and pumps.

Automotive: Engine and exhaust components using 304 and 410 stainless steel.

Data Insight: According to a 2022 Foundry Industry Survey, 68% of chemical processing foundries chose stainless steel investment casting for corrosion-sensitive parts, while 57% of aerospace foundries relied on 17-4 PH stainless steel for high-strength components.

Cost and Efficiency Considerations

While investment casting stainless steel has higher upfront costs, proper material selection, thermal management, and post-casting treatment can reduce long-term maintenance, scrap, and rework, ultimately increasing ROI.

Factors Affecting Cost:

- Stainless steel grade selection

- Mold and shell complexity

- Thermal and pouring control systems

- Post-casting treatments and quality assurance

Tip: Combining automated process monitoring with skilled operator oversight can reduce production defects by up to 35%, according to Global Casting Solutions 2022.

Conclusion

Mastering the four essential strategies for stainless steel investment casting—selecting the right grade, optimizing molds, controlling thermal conditions, and post-casting treatments—ensures high-quality, precise, and durable components. Implementing these strategies reduces defects, improves production efficiency, and guarantees compliance with industrial standards across aerospace, medical, chemical, and automotive applications. Following these best practices and leveraging expert insights allows manufacturers to maximize ROI while producing reliable stainless steel investment casting components for modern industry.

FAQ

Q: Which stainless steel grade resists chemical corrosion best?

A: 316 stainless steel due to high chloride and chemical resistance.

Q: How can small workshops achieve high-quality investment casting?

A: Precision mold design, controlled pouring, and post-casting inspection are key.

Q: Can porosity be completely eliminated?

A: While difficult, vacuum-assisted pouring and optimized thermal control can minimize it.

Q: Is investment casting always cost-effective for large parts?

A: For simple, large components, sand casting may be cheaper; for complex geometries, investment casting is preferable.

Q: What post-casting tests are essential?

A: Dimensional inspection, NDT, corrosion tests, and mechanical testing are recommended.

Q: Are hybrid material solutions feasible?

A: Yes, combining stainless steel with other metals can optimize performance and reduce costs.

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF