Pengeluar Tuangan Pendesak :5 Bendera Merah Semasa Memilih

Selamat Datang ke Blog Saya!

Saya teruja untuk mempunyai anda di sini! Sebelum kita menyelami kandungan, saya ingin anda menyertai saya di platform media sosial saya. Di situlah saya berkongsi cerapan tambahan, berhubung dengan komuniti kami yang hebat dan memaklumkan anda tentang berita terkini. Begini cara anda boleh terus berhubung:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Sekarang, mari kita mulakan perjalanan ini bersama-sama! Saya harap anda mendapati kandungan di sini bukan sahaja bernas tetapi juga memberi inspirasi dan berharga. Mari mulakan!

Jadual Kandungan

pengenalan

Dalam industri seperti rawatan air, penjanaan kuasa, kejuruteraan marin, dan pemprosesan kimia, pendesak memainkan peranan penting dalam memastikan pergerakan bendalir dan pemindahan tenaga. Pendesak ini mestilah tahan lama, cekap dan tahan haus dan kakisan. Di sebalik setiap pendesak yang boleh dipercayai adalah kualiti pengilang tuangan pendesak yang memahami selok-belok metalurgi, kejuruteraan ketepatan dan keperluan prestasi.

Walau bagaimanapun, tidak semua pengeluar dicipta sama. Memilih pembekal yang salah boleh mengakibatkan masa henti yang mahal, prestasi produk di bawah taraf dan potensi risiko keselamatan. Sama ada anda mendapatkan sumber untuk pam industri, turbin atau pemampat, adalah penting untuk melihat tanda merah awal sebelum membuat komitmen perkongsian.

Artikel ini meneroka lima tanda amaran utama yang pengilang tuangan pendesak mungkin tidak sesuai untuk projek anda. Dengan mengenal pasti isu ini lebih awal, anda boleh membuat keputusan yang lebih termaklum dan mendapatkan rakan kongsi pembuatan jangka panjang yang memenuhi keperluan teknikal, kawal selia dan prestasi anda.

Bendera Merah 1: Kekurangan Pensijilan dan Standard Kualiti

Pengilang tuangan pendesak yang boleh dipercayai harus mematuhi piawaian dan pensijilan antarabangsa yang diiktiraf. Jika pembekal tidak dapat memberikan bukti pematuhan terhadap protokol industri, itu adalah tanda amaran utama pertama anda dan harus segera menimbangkan semula kesesuaian mereka.

Mengapa Pensijilan Penting

Pensijilan seperti ISO 9001, ASME atau PED mengesahkan bahawa a pengilang tuangan pendesak mengikuti proses piawai untuk jaminan kualiti, keselamatan dan ketekalan. Ini bukan sekadar formaliti—ia adalah jaminan bahawa setiap produk cast telah menjalani pemeriksaan kualiti yang ketat. Tanpa mereka, anda mungkin menerima pendesak yang mengalami metalurgi yang tidak konsisten, dimensi yang tidak wajar atau kegagalan prestasi yang boleh mengganggu operasi dan meningkatkan kos jangka panjang.

Pengilang tuangan pendesak yang diperakui selalunya akan memaparkan bukti kelayakan mereka secara telus dan bersedia untuk membincangkan sistem pengurusan kualiti mereka secara terperinci. Pematuhan mereka kepada piawaian kualiti yang diiktiraf di peringkat antarabangsa bukan sahaja penunjuk kecekapan tetapi juga tanda komitmen terhadap kecemerlangan.

Bendera Merah 2: Prosedur Pengujian dan Pemeriksaan yang Tidak Mencukupi

Produk yang boleh dipercayai memerlukan ujian yang ketat sepanjang proses pembuatan. Pengilang tuangan pendesak yang melangkau atau meminimumkan langkah pemeriksaan boleh menjejaskan keseluruhan operasi anda. Kekurangan prosedur pemeriksaan yang betul boleh menyebabkan kelemahan struktur, ketidakkonsistenan bahan, atau kegagalan awal pendesak di lapangan.

Apa Yang Anda Patut Jangkakan

Protokol pemeriksaan hendaklah termasuk:

- Ujian tidak merosakkan (NDT)

- Pemeriksaan dimensi

- Analisis komposisi bahan

- Ujian tekanan (apabila berkenaan)

Tanya kepada pengilang tuangan pendesak untuk rekod laporan pemeriksaan lepas dan sijil pematuhan. Ketelusan dalam bidang ini ialah penunjuk yang baik bagi integriti operasi dan kebolehpercayaan produk. Pengilang yang mengutamakan ujian menyeluruh berkemungkinan besar untuk menyampaikan tuangan pendesak yang tahan lama dan berprestasi tinggi secara konsisten. iliti.

Bendera Merah 3: Komunikasi dan Sokongan Pelanggan yang Lemah

Komunikasi yang berkesan adalah tanda profesionalisme dan kawalan proses. Jika pengilang tuangan pendesak lambat bertindak balas, kabur dalam jawapan mereka atau mengetepikan kebimbangan teknikal anda, itu adalah tanda merah yang serius. Komunikasi adalah penting pada setiap langkah, daripada perundingan reka bentuk dan sebut harga kepada penjadualan penghantaran dan sokongan selepas jualan.

Piawaian Komunikasi yang Perlu Diperhatikan

- Maklum balas segera kepada pertanyaan

- Pengetahuan teknikal daripada kakitangan jualan atau kejuruteraan

- Garis masa pengeluaran yang jelas dan jangkaan penghantaran

- Kesediaan untuk menawarkan sokongan selepas jualan

Pengilang tuangan pendesak yang menghargai hubungan jangka panjang akan mengutamakan ketelusan dan perkhidmatan daripada perbualan pertama. Talian komunikasi terbuka membantu memastikan pemahaman bersama tentang keperluan projek, yang mengurangkan risiko salah faham yang mahal atau kelewatan penghantaran.

Bendera Merah 4: Tiada Rekod Kesan Terbukti dalam Industri Anda

Pengalaman dalam pemutus umum tidak selalu mencukupi. Pengeluar tuangan pendesak terbaik untuk keperluan anda harus mempunyai sejarah menghasilkan komponen untuk aplikasi atau industri khusus anda. Kekurangan pengalaman khusus industri boleh mengakibatkan pilihan bahan yang tidak sesuai, panduan reka bentuk yang tidak mencukupi atau isu prestasi.

Mengapa Pengalaman Industri Penting

Industri yang berbeza mempunyai cabaran yang berbeza:

- Loji kimia memerlukan aloi tahan kakisan

- Sistem marin menuntut ketahanan terhadap biofouling

- Peralatan penjanaan kuasa mungkin beroperasi di bawah haba dan tekanan yang melampau

Seorang yang berpengetahuan pengilang tuangan pendesak dengan pengalaman industri akan memahami persekitaran operasi peralatan anda. Mereka boleh menawarkan cerapan tentang amalan terbaik, pemilihan bahan dan pengubahsuaian reka bentuk yang meningkatkan ketahanan dan kecekapan pendesak anda.

Jadual: Perbandingan bagi Pengeluar Tuangan Pendesak Bendera Merah

| Bendera Merah | Mengapa Ia Penting | Apa yang Perlu Diminta |

|---|---|---|

| Tiada pensijilan | Menunjukkan kekurangan kawalan kualiti piawai | Minta sijil ISO, ASME atau PED |

| Pemeriksaan yang tidak mencukupi | Risiko kegagalan produk dan isu pematuhan | Minta laporan ujian NDT dan bahan |

| Komunikasi yang lemah | Boleh menyebabkan kelewatan dan salah faham teknikal | Nilai responsif dan kepakaran |

| Tiada pengalaman industri | Boleh menghasilkan tuangan yang tidak memenuhi keperluan anda | Minta kajian kes atau rujukan industri |

| Peralatan pengeluaran yang ketinggalan zaman | Hadkan ketepatan dan kualiti | Tanya tentang peningkatan peralatan terkini |

Bendera Merah 5: Peralatan dan Proses Pengeluaran Lapuk

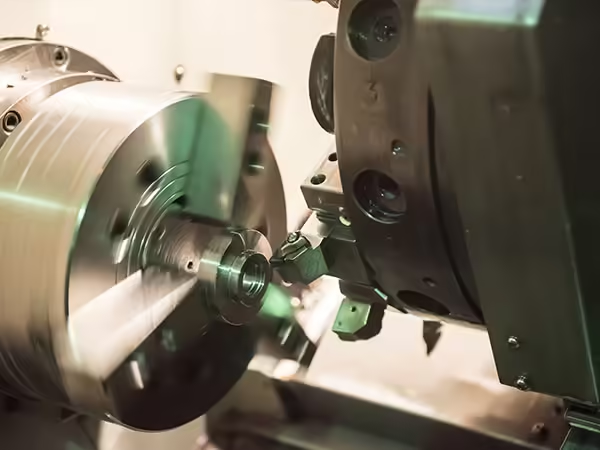

Teknologi tuangan lanjutan menghasilkan pendesak yang lebih tepat, tahan lama dan boleh dipercayai. Jika an pengilang tuangan pendesak menggunakan jentera usang atau tidak melabur dalam penambahbaikan berterusan, pengeluarannya mungkin kurang.

Teknologi yang Perlu Anda Cari

- Keupayaan pemesinan CNC

- Sistem pembuatan acuan automatik

- Teknik pencairan dan penuangan moden

- Alat simulasi dan pemodelan dalaman

Inovasi dalam amalan faundri mencerminkan komitmen terhadap kualiti, keselamatan dan daya saing jangka panjang.

Kesimpulan

Memilih yang betul pengilang tuangan pendesak adalah lebih kurang daripada kos dan tarikh penghantaran. Ini mengenai kebolehpercayaan, keselamatan dan prestasi jangka panjang. Bendera merah yang telah kami bincangkan—dari kekurangan pensijilan kepada proses lapuk—adalah isyarat bahawa pengilang mungkin tidak memenuhi permintaan projek anda.

Dengan bertanya soalan yang betul dan menilai pembekal berdasarkan ketelusan, kepakaran teknikal dan pengalaman industri mereka, anda boleh mengelakkan ralat yang mahal dan memastikan ROI yang lebih baik.

Pada kali seterusnya anda memilih pengilang, ingat: kewaspadaan hari ini menghalang bencana esok. Utamakan kualiti, komunikasi dan inovasi untuk mendapatkan rakan kongsi pembuatan yang boleh anda percayai.

Soalan Lazim

Apakah pensijilan yang perlu saya cari dalam pengeluar tuangan pendesak?

Cari pensijilan seperti ISO 9001, ASME dan PED, yang menunjukkan pengurusan kualiti dan pematuhan kepada piawaian antarabangsa. Pensijilan khusus industri juga mungkin diperlukan bergantung pada aplikasi anda, memastikan pengeluar tuangan pendesak memenuhi piawaian prestasi dan keselamatan.

Seberapa penting pengalaman industri?

Pengalaman industri adalah penting. Pengeluar tuangan pendesak yang berpengalaman dalam sektor anda akan memahami keperluan khusus anda, sama ada untuk loji kimia, sistem marin atau penjanaan kuasa, memastikan bahan dan prestasi yang betul.

Bolehkah komunikasi yang lemah memberi kesan kepada pengeluaran?

Ya, komunikasi yang lemah boleh menyebabkan kesilapan dalam spesifikasi, kelewatan dan ralat dalam pengeluaran. Pengeluar tuangan pendesak responsif dengan komunikasi yang jelas membantu mengelakkan salah faham dan memastikan penghantaran produk berkualiti tepat pada masanya.

Perlukah saya melawat kemudahan pengilang?

Mengunjungi kemudahan adalah idea yang baik. Ia membolehkan anda menilai peralatan pengilang, proses dan kawalan kualiti keseluruhan, memastikan ia dapat memenuhi keperluan tuangan anda dan mengekalkan standard pengeluaran yang tinggi.

Bagaimanakah saya boleh mengesahkan piawaian pemeriksaan pengilang?

Minta dokumentasi laporan pemeriksaan lepas dan pensijilan yang berkaitan dengan ujian. Ini memastikan pengilang tuangan pendesak mengikut prosedur kawalan kualiti yang betul dan menjamin kebolehpercayaan produk.

Kategori Produk

- Bahagian Injap

- Bahagian Pam Air

- Bahagian Kotak Galas

- Bahagian Die Casting

- Produk Pam Keluli Tahan Karat

- Produk Pam Besi Tuang

- Bahagian Injap Untuk Kegunaan Kereta

- Bahagian Kenderaan

- Bahagian Injap Untuk Kegunaan Awam

- Bahagian Pam Vakum KF