Was ist ein Pumpenlaufrad? 9 wesentliche Merkmale

Willkommen auf meinem Blog!

Ich freue mich sehr, dass du hier bist! Bevor wir uns in die Inhalte vertiefen, würde ich mich freuen, wenn du mir auf meinen Social-Media-Plattformen folgst. Dort teile ich zusätzliche Einblicke, vernetze mich mit unserer großartigen Community und halte dich über die neuesten Nachrichten auf dem Laufenden. So bleibst du in Verbindung:

📘 Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Lassen Sie uns gemeinsam auf diese Reise gehen! Ich hoffe, Sie finden die Inhalte hier nicht nur aufschlussreich, sondern auch inspirierend und wertvoll. Los geht‘s!

Inhaltsverzeichnis

Einführung

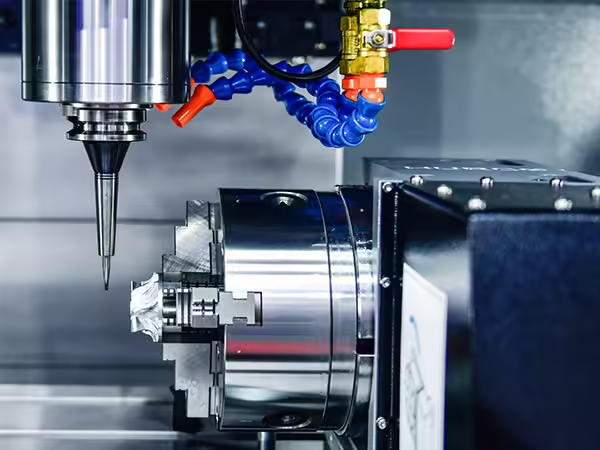

Understanding what is a pump impeller is fundamental to grasping how centrifugal and other types of pumps function. The impeller is the component that transmits energy from the motor to the fluid being pumped, enabling movement through the system. It does this by spinning and applying centrifugal force to the fluid, increasing its velocity and pressure. Whether you’re in the chemical industry, water treatment, or HVAC, the efficiency and design of the impeller are crucial for system performance. To fully comprehend what is a pump impeller, it’s essential to recognize its role in energy conversion and fluid dynamics.

Its design can drastically affect the overall effectiveness of a pump, making it a key factor in optimizing pump efficiency and functionality across various applications. Thus, knowing what is a pump impeller and how it operates is vital for selecting the right pump for your needs.

The Role of the Pump Impeller in Fluid Dynamics

To truly grasp what is a pump impeller, it’s essential to explore its fundamental function within the principles of fluid dynamics. A pump impeller is the rotating component inside a centrifugal pump that plays a pivotal role in moving fluid efficiently. As the impeller spins, it creates a low-pressure zone at the eye or center, drawing liquid inward. Through centrifugal force, the fluid is then flung outward along the impeller vanes, accelerating and gaining kinetic energy. This transformation from mechanical to kinetic energy propels the fluid outward through the pump casing and eventually out via the discharge pipe.

Understanding what is a pump impeller involves more than just identifying it as a rotating part. The energy conversion it performs is central to the pump’s overall operation. The efficiency of this process is influenced by several factors, including the design, size, and material composition of the impeller. These factors directly determine how well the pump performs in different fluid applications and operating environments. The better the impeller design and materials, the more efficient the pump will be at handling a variety of fluids and maximizing its energy conversion.

9 Essential Features of a Pump Impeller

When asking what is a pump impeller, it’s important to look at its key features. These features influence the performance of the impeller under different operating conditions and are crucial in choosing the right impeller for your needs.

Material Composition

The material composition of a pump impeller plays a critical role in its performance and longevity. Common materials include stainless steel, cast iron, bronze, and engineered plastics. The material chosen depends on the type of fluid being handled. For example, stainless steel is often used for clean water and non-corrosive fluids, while bronze and other alloys are preferred for more aggressive chemicals.

Number of Vanes

The number of vanes in a pump impeller can affect its efficiency. More vanes can increase the efficiency of the pump by improving fluid movement. However, fewer vanes reduce the risk of clogging in applications like slurry handling, where solid particles might obstruct flow. Understanding what is a pump impeller also involves knowing how the vane count impacts flow rates and maintenance.

Impeller Diameter

The impeller diameter directly influences the pump’s flow and head characteristics. A larger diameter generally provides more flow capacity but may reduce the pump’s efficiency if not paired with the appropriate motor and speed. Smaller diameters often offer higher head pressure but may struggle with large volumes of fluid. Understanding what is a pump impeller also means understanding how its size impacts overall pump performance.

Open, Semi-Open, or Closed Design

The design of the impeller—open, semi-open, or closed—determines its suitability for different types of fluids. Open impellers are ideal for handling fluids containing solids, as the open vanes are less likely to clog. Semi-open impellers balance efficiency and solids handling, while closed impellers are highly efficient but may be prone to clogging in solids-laden fluids.

Balance and Alignment

Proper balance and alignment are vital for maintaining the pump impeller’s performance. An unbalanced impeller can lead to vibrations, increased wear, and even failure of the pump. Regular checks on balance and alignment are key to ensuring the impeller runs smoothly and the pump operates at peak efficiency.

Comparing Different Impeller Designs

When considering what is a pump impeller, it’s essential to compare different impeller designs and understand their applications. The choice of impeller design directly impacts efficiency, reliability, and the ability to handle various fluids. Below is a comparison of common impeller types used in pumps.

| Impeller Type | Beschreibung | Vorteile | Nachteile |

|---|---|---|---|

| Open | Vanes are visible and not covered by shrouds | Good for handling solids, easy to clean | Lower efficiency, wear-prone |

| Semi-Open | One side is shrouded | Balance of efficiency and solids handling | Moderate clogging risk |

| Closed | Both sides are shrouded | High efficiency, best for clean fluids | Prone to clogging with solids |

| Vortex | Uses whirlpool motion | Excellent for solids | Lower energy efficiency |

| Channel | Channels instead of vanes | Low clogging, good for sewage | Lower flow control |

Performance Factors Influencing What Is a Pump Impeller

The performance of a pump impeller can be affected by several factors, and understanding these factors is crucial for selecting the right impeller for your application. These factors determine how well the impeller will handle various fluids and operate under different conditions.

Rotational Speed

Rotational speed is one of the most important factors when considering what is a pump impeller. Higher RPMs generate greater centrifugal force, which can improve fluid flow and increase the efficiency of the pump. However, higher speeds also place more strain on the impeller, requiring robust material and design.

Fluid Type

Different types of fluids require different impeller designs. Clean water, for instance, can be pumped with a standard impeller, while more viscous or abrasive fluids may require a more specialized impeller. Impeller materials and designs are chosen based on the specific characteristics of the fluid being pumped.

Viscosity

Viscous fluids require more energy to move, which means that impeller design must compensate for this. Thicker fluids may reduce the pump’s efficiency if the impeller is not designed to handle them, necessitating specialized impellers with features to reduce drag and improve flow.

System Head

The required pressure, or system head, influences the impeller size and shape. Higher head pressure demands larger impellers with greater strength to handle the added resistance. The design must balance flow rates and head pressure to maintain efficiency.

Installation and Maintenance Best Practices

Understanding what is a pump impeller also involves knowing how to install and maintain it properly. Proper maintenance ensures that the impeller continues to perform optimally and extends the lifespan of the pump.

Alignment Check

Misalignment is one of the most common causes of impeller wear. Regular alignment checks are crucial to ensure that the impeller remains properly centered within the pump casing and operates efficiently without excessive wear.

Lubrication

The bearings and seals of the pump impeller require regular lubrication to prevent friction and wear. Inadequate lubrication can lead to increased operating temperatures and damage to the pump components.

Impeller Clearance

The clearance between the impeller and the pump casing should be checked regularly. Too much clearance reduces efficiency, while too little clearance can lead to friction and damage.

Reinigung

Impeller performance can be affected by the build-up of solids or debris on the vanes. Regular cleaning is necessary to maintain proper fluid flow and avoid balance issues.

Replacement

As impellers wear down, their ability to efficiently pump fluid diminishes. When impellers are worn beyond their tolerances, it’s essential to replace them promptly to avoid damaging the pump or reducing performance.

Abschluss

Choosing the right impeller begins with understanding what is a pump impeller and how its features align with your system’s needs. Understanding what is a pump impeller is crucial in making the right choice. From materials and vane configurations to maintenance and energy efficiency, each aspect plays a role in operational success. A well-matched impeller, informed by a clear understanding of what is a pump impeller, leads to reduced downtime, better flow control, and lower total cost of ownership. Therefore, knowing what is a pump impeller and how its specific characteristics match your application is key to achieving optimal pump performance.

Häufig gestellte Fragen

What is a pump impeller and how does it work?

A pump impeller is a rotating component inside a centrifugal pump that converts mechanical energy into kinetic energy, moving fluid through the pump.

What materials are used for pump impellers?

Common materials include stainless steel, cast iron, bronze, and engineered plastics, with the choice depending on the fluid being handled.

How do I know which impeller design is best for my pump?

The design choice depends on the type of fluid being pumped and whether solids handling or high-efficiency pumping is required.

What causes pump impellers to wear?

Wear can be caused by misalignment, lack of lubrication, excessive clearance, or the build-up of solids on the impeller.

Can I clean a pump impeller?

Yes, regular cleaning is necessary to maintain optimal performance, especially when dealing with fluids containing solids or debris.

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF