3 versteckte Gefahren in Pumpenlaufrädern aus Gusseisen

Willkommen auf meinem Blog!

Ich freue mich sehr, dass du hier bist! Bevor wir uns in die Inhalte vertiefen, würde ich mich freuen, wenn du mir auf meinen Social-Media-Plattformen folgst. Dort teile ich zusätzliche Einblicke, vernetze mich mit unserer großartigen Community und halte dich über die neuesten Nachrichten auf dem Laufenden. So bleibst du in Verbindung:

📘 Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Lassen Sie uns gemeinsam auf diese Reise gehen! Ich hoffe, Sie finden die Inhalte hier nicht nur aufschlussreich, sondern auch inspirierend und wertvoll. Los geht‘s!

Inhaltsverzeichnis

Einführung

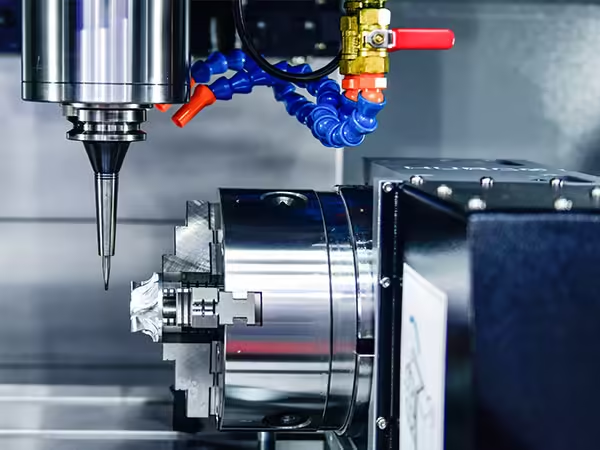

Pumpenlaufräder aus Gusseisen Gusseisen-Pumpenlaufräder spielen eine entscheidende Rolle in vielen Systemen zur Förderung von Flüssigkeiten in Branchen wie Landwirtschaft, Abwasserbehandlung und chemischer Verarbeitung. Bekannt für ihre Langlebigkeit und Wirtschaftlichkeit, werden diese Komponenten häufig für Pumpen eingesetzt, die eine robuste Leistung erfordern. Trotz ihrer vielen Vorteile kann die ausschließliche Verwendung von Gusseisen-Pumpenlaufrädern zu unerwarteten Problemen führen. Dieser Artikel deckt drei versteckte Gefahren im Zusammenhang mit Gusseisen-Pumpenlaufrädern auf und untersucht deren Auswirkungen auf Leistung, Sicherheit und langfristige Betriebskosten.

Das Verständnis dieser Risiken ist für Ingenieure, Techniker und Wartungsteams unerlässlich, um die Effizienz und Lebensdauer von Pumpenanlagen zu maximieren. Durch die Kenntnis der Schwachstellen des Gusseisen-Pumpenlaufrads können die Beteiligten proaktive Strategien zur Vermeidung von Ausfällen und zur Gewährleistung eines reibungslosen Betriebs umsetzen.

Das Korrosionsrätsel in Pumpenlaufräder aus Gusseisen

Eine der bedeutendsten, aber oft unterschätzten Gefahren ist Korrosion. Gusseisen bietet zwar eine ausgezeichnete mechanische Festigkeit, neigt aber bei Kontakt mit Feuchtigkeit, Chemikalien oder sauren Flüssigkeiten von Natur aus zu Oxidation und Rost. Dieser Korrosionsprozess kann die Oberfläche und die strukturelle Integrität des Laufrads rasch beeinträchtigen.

Pumpen, die in rauen Umgebungen oder beim Fördern aggressiver Flüssigkeiten eingesetzt werden, können einem beschleunigten Verschleiß unterliegen, was ihre Lebensdauer verkürzt. Korrosion beeinträchtigt nicht nur das Aussehen des Gusseisen-Pumpenlaufrads, sondern mindert auch dessen hydraulische Leistung, was zu reduzierten Fördermengen und geringerer Energieeffizienz führt. Unbehandelt kann Korrosion zudem zu einem Totalausfall führen, der kostspielige Reparaturen und ungeplante Stillstandszeiten nach sich zieht.

Häufig vorkommende Korrosionsarten

- Gleichmäßige KorrosionGleichmäßige Oberflächenrostbildung aufgrund ständiger Flüssigkeitseinwirkung.

- Lochkorrosion: Lokalisierte und intensive Korrosion, die Hohlräume bildet.

- Galvanische KorrosionVerursacht durch den Kontakt mit ungleichen Metallen im Pumpengehäuse.

Geeignete Materialbeschichtungen, eine verbesserte Fluidchemie und regelmäßige Inspektionen können dazu beitragen, diese Risiken zu mindern.

Herausforderungen durch mechanischen Verschleiß und Erosion

Mechanischer Verschleiß und Erosion stellen eine weitere versteckte Gefahr dar in Pumpenlaufräder aus Gusseisen, Dies gilt insbesondere für Anwendungen, die den Transport von abrasiven oder partikelhaltigen Flüssigkeiten beinhalten. Diese Kräfte können nicht nur die Oberflächenbeschaffenheit des Laufrads, sondern auch seine kritischen Abmessungen beeinträchtigen, was zu einem fortschreitenden Rückgang der Pumpeneffizienz und -zuverlässigkeit führt.

Wenn abrasive Partikel wie Sand, Kies oder Schlamm mit hoher Geschwindigkeit durch die Pumpe strömen, wirken sie wie winzige Geschosse, die wiederholt auf die Laufradoberfläche treffen. Dies führt zu einem allmählichen Materialabtrag, insbesondere an den Schaufelspitzen und -kanten, wo die Strömungsgeschwindigkeit am höchsten ist. Mit der Zeit kann diese Erosion zu erheblichen Dimensionsänderungen des Laufrads führen, was das hydraulische Gleichgewicht beeinträchtigt und den Flüssigkeitsfluss behindert.

Darüber hinaus erhöhen die durch Erosion verursachten Oberflächenrauhigkeiten die Turbulenzen, was die Kavitation – ein Phänomen, bei dem sich Dampfblasen im Inneren der Pumpe bilden und zusammenfallen – verstärken kann. Kavitation beschleunigt nicht nur den Verschleiß, sondern kann auch zu Lochfraß führen und den Zustand des Laufrads verschlechtern.

Wichtigste Indikatoren für mechanischen Verschleiß

- Ausdünnung der Flügelkanten: Mit fortschreitendem Materialverschleiß werden die Schaufeln dünner, wodurch ihre Festigkeit und ihre Fähigkeit, Energie an das Fluid abzugeben, abnehmen.

- OberflächenrauheitDie ehemals glatten Oberflächen entwickeln Lochfraß, Kratzer und ungleichmäßige Abnutzungsmuster, was den Strömungswiderstand erhöht.

- Reduzierte Förderhöhe und DruckEin klares Zeichen dafür, dass das Laufrad aufgrund von Geometrieverlusten die Flüssigkeit nicht mehr mit der gleichen Kraft bewegen kann.

- Unregelmäßige StrömungsmusterSchwankungen im Ausgangsdruck oder pulsierende Durchflussmengen können auf ein Ungleichgewicht oder eine hydraulische Ineffizienz hinweisen.

- Erhöhtes BetriebsgeräuschHohe Pfeiftöne oder rasselnde Geräusche können auf ungleichmäßigen Verschleiß oder eine fehlerhafte Ausrichtung des Laufrads hinweisen.

Um diesen Problemen entgegenzuwirken, sollten Wartungsteams regelmäßig Wartungsarbeiten durchführen. Partikelgrößen- und Konzentrationsanalyse Zur Beurteilung der Abrasivität des Fluids. Bei hohen Partikelkonzentrationen kann der Einsatz verschleißfester Beschichtungen – wie beispielsweise Wolframcarbid- oder Keramikauskleidungen – von Vorteil sein. Unter extremen Bedingungen kann der Einsatz von Laufrädern aus härteren Materialien wie Edelstahl oder Duplexlegierungen erforderlich sein.

Bewährte Verfahren zur Minimierung des mechanischen Verschleißes

- Installieren Sie Filter oder Siebe um große abrasive Partikel stromaufwärts zu entfernen.

- Pumpendrehzahl und Durchflussraten optimieren um die Strömungsgeschwindigkeit zu verringern und die Aufprallkräfte zu minimieren.

- Verwenden Sie erosionsbeständige Beschichtungen oder Hartauftragsmaterialien. auf Laufradoberflächen.

- Laufräder mit dickeren Schaufelprofilen konstruieren für Anwendungen mit hoher Abriebbelastung.

- Vibrationen und Ausrichtung überwachen regelmäßig, um zusätzliche mechanische Belastungen zu vermeiden.

Durch die proaktive Bekämpfung von Erosion und mechanischem Verschleiß können die Betreiber die Effizienz erhalten und die Lebensdauer von Gusseisen-Pumpenlaufrädern verlängern, insbesondere in anspruchsvollen industriellen Umgebungen.

Sprödbruch unter extremen Bedingungen

Obwohl Gusseisen für seine hohe Druckfestigkeit bekannt ist, neigt es unter Zugspannung oder Stoßbelastung zur Sprödigkeit. Das bedeutet, dass das Pumpenlaufrad aus Gusseisen bei plötzlichen Druckänderungen, mechanischen Stößen oder unsachgemäßer Installation anfällig für Risse oder plötzlichen Bruch ist.

In kalten Klimazonen kann die thermische Kontraktion das Problem verschärfen und die Wahrscheinlichkeit von Brüchen beim An- und Abfahren erhöhen. Ein Sprödbruch kann den Betrieb vollständig zum Erliegen bringen und insbesondere in Hochdrucksystemen sogar Sicherheitsrisiken für das Personal bergen. Die richtige Materialauswahl und eine sorgfältige Konstruktionsprüfung sind daher entscheidend, um dieses Risiko zu minimieren.

Häufige Szenarien, die zu Knochenbrüchen führen:

- Gefrierende Flüssigkeit im Pumpengehäuse

- Schnelle Start-Stopp-Zyklen

- Plötzliches Schließen von Ventilen verursacht Wasserschlag

- Falsch ausgerichtete Motorkupplungen

Tabelle: Vergleichsanalyse von Pumpenlaufradmaterialien

| Eigentum | Gusseisen | Bronze | Edelstahl | Technischer Kunststoff |

|---|---|---|---|---|

| Korrosionsbeständigkeit | Schlecht bis mittelmäßig | Gut | Exzellent | Exzellent |

| Abriebfestigkeit | Mäßig | Mäßig | Gut | Niedrig bis mittel |

| Stärke | Hoch (kompressiv) | Mäßig | Hoch | Mäßig |

| Sprödigkeit | Hoch | Niedrig | Niedrig | Sehr niedrig |

| Kosten | Niedrig | Mäßig | Hoch | Niedrig bis mittel |

| Häufige Anwendungen | Abwasser, Landwirtschaft | Marine, Öl | Chemikalien, Lebensmittelverarbeitung | Leichte, korrosive Flüssigkeiten |

Die obige Tabelle bietet einen vergleichenden Überblick über verschiedene Materialien, die üblicherweise für Pumpenlaufräder verwendet werden, und hebt sowohl die Vorteile als auch die Grenzen des Pumpenlaufrads aus Gusseisen im Vergleich zu Alternativen hervor.

Früherkennung von Ausfallerscheinungen an Pumpenlaufrädern aus Gusseisen

Die vorbeugende Wartung spielt eine entscheidende Rolle bei der Verlängerung der Lebensdauer von Pumpenlaufräder aus Gusseisen. Das frühzeitige Erkennen von Verschleißerscheinungen kann katastrophale Ausfälle verhindern und Reparaturkosten senken. Hier sind einige wichtige Frühindikatoren, die nicht übersehen werden sollten:

- Ungewöhnliche GeräuscheEin rasselndes, schleifendes oder pfeifendes Geräusch aus der Pumpe deutet oft auf eine Unwucht, eine Fehlausrichtung oder Verschleiß am Laufrad hin. Diese Geräusche können sich mit der Zeit verschlimmern und sollten umgehend untersucht werden.

- Reduzierter DurchflussEin merklicher Rückgang der Pumpenleistung, wie z. B. eine langsamere Flüssigkeitsbewegung oder ein verringerter Druck, kann auf Erosion, Korrosion oder Verformung der Laufradschaufeln hinweisen.

- Sichtbare Risse oder RostfleckenOberflächenfehler, insbesondere an den Klingenwurzeln oder Befestigungspunkten, können Vorboten tieferer Risse sein. Rost kann sich in feuchter Umgebung schnell ausbreiten und die Struktur schwächen.

- Erhöhte VibrationUngewöhnliche Vibrationen werden häufig durch asymmetrischen Verschleiß, Ablagerungen oder innere Risse verursacht. Anhaltende Vibrationen schädigen nicht nur die Pumpe, sondern können auch angeschlossene Geräte beeinträchtigen.

- Häufige WartungszyklenWenn eine Pumpe immer häufiger Reparaturen oder Inspektionen benötigt, kann dies darauf hindeuten, dass das Laufrad aufgrund kumulativer Schäden schneller verschleißt als erwartet.

Zur Verbesserung der Früherkennung sollten Wartungsteams die folgenden Diagnoseverfahren anwenden:

- Regelmäßige Sichtprüfungen mittels Endoskopen oder Demontage

- Schwingungsanalyse um Amplituden- und Frequenzverschiebungen zu verfolgen

- Ultraschallprüfung zur Erkennung interner Fehler

- Flüssigkeitsprobenahme zur Beurteilung der chemischen Aggressivität oder des Partikelgehalts

Durch die Implementierung eines proaktiven Zustandsüberwachungsprogramms können Anlagenbetreiber rechtzeitig Reparaturen oder Austauschmaßnahmen planen und so Ausfallzeiten minimieren und die Lebensdauer der Anlagen maximieren.

Alternative Werkstoffe und ihre Auswirkungen auf die Leistung

Bei Anlagen mit häufigen Ausfällen oder Wartungsproblemen kann der Wechsel zu einem alternativen Laufradmaterial die Zuverlässigkeit verbessern. Laufräder aus Edelstahl bieten eine hervorragende Korrosions- und Verschleißbeständigkeit, während Bronze eine bessere Duktilität und geringere Sprödigkeit aufweist. In weniger anspruchsvollen Umgebungen können Hochleistungskunststoffe Korrosionsbeständigkeit bei geringerem Gewicht und niedrigeren Kosten bieten.

Materialänderungen sollten jedoch nur unter Berücksichtigung der Anwendung, der Fluideigenschaften und der Betriebsbedingungen erfolgen. Jedes Material hat Vor- und Nachteile, die neben den Leistungserwartungen und Budgetbeschränkungen abgewogen werden müssen.

Fragen, die vor dem Materialwechsel geklärt werden sollten

- Wie hoch sind die gesamten Besitzkosten über die gesamte Lebensdauer der Pumpe?

- Welche chemische Zusammensetzung hat die gepumpte Flüssigkeit?

- Sind feste Partikel in der Flüssigkeit vorhanden?

- Sind die Betriebstemperatur oder der Betriebsdruck extrem?

- Wie häufig ist derzeit eine Wartung erforderlich?

Abschluss

Während Pumpenlaufräder aus Gusseisen Pumpen sind aufgrund ihrer Erschwinglichkeit und Robustheit nach wie vor eine beliebte Wahl für viele Anwendungen, bergen aber auch versteckte Gefahren. Korrosion, mechanischer Verschleiß und Versprödung können die Pumpenleistung beeinträchtigen und die Betriebskosten erhöhen, wenn sie nicht sachgemäß behandelt werden.

Durch die Identifizierung dieser Risiken und die Anwendung proaktiver Strategien wie Materialbewertung, planmäßige Wartung und regelmäßige Inspektionen können Betreiber Ausfälle minimieren und die langfristige Systemzuverlässigkeit sicherstellen. Bei häufigen Störungen kann die Untersuchung alternativer Laufradmaterialien zu deutlichen Leistungsverbesserungen führen.

Letztendlich ist das Verständnis der Grenzen des Pumpenlaufrads aus Gusseisen der Schlüssel zu fundierten Entscheidungen bei der Konstruktion und Wartung von Pumpensystemen.

Häufig gestellte Fragen

Wie oft sollte ein Pumpenlaufrad aus Gusseisen inspiziert werden?

Die Inspektionshäufigkeit hängt von der Anwendung ab, in anspruchsvollen Umgebungen wird jedoch eine vierteljährliche Inspektion empfohlen.

Kann ein Pumpenlaufrad aus Gusseisen Können sie im Schadensfall repariert werden?

Kleinere Oberflächenschäden können manchmal repariert werden, aber umfangreiche Korrosion oder Risse erfordern in der Regel einen Austausch.

Welche Flüssigkeiten sind am schädlichsten für Pumpenlaufräder aus Gusseisen?

Saure, alkalische oder abrasive Flüssigkeiten können die Lebensdauer eines Pumpenlaufrads aus Gusseisen erheblich verkürzen.

Sind Beschichtungen wirksam beim Schutz von Laufrädern aus Gusseisen?

Ja, bestimmte Schutzbeschichtungen können die Korrosionsbeständigkeit verbessern, verhindern aber möglicherweise nicht den mechanischen Verschleiß.

Wann sollte ich den Wechsel zu einem anderen Laufradmaterial in Betracht ziehen??

Wenn es in Ihrem System häufig zu Laufradausfällen oder erhöhten Wartungskosten kommt, bieten alternative Werkstoffe wie Edelstahl möglicherweise eine längere Lebensdauer.

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF