أهم 7 اتجاهات في تشكيل الأجزاء الميكانيكية المعدنية

مرحباً بكم في مدونتي!

يسعدني وجودك هنا! قبل أن نتعمق في المحتوى، أود أن تنضموا إليّ على منصات التواصل الاجتماعي. هناك أشارككم أفكارًا إضافية، وأتواصل مع مجتمعنا الرائع، وأُطلعكم على آخر الأخبار. إليكم كيفية البقاء على تواصل:

📘 فيسبوك: شركة شنغهاي لييروو الصناعية التجارية المحدودة

الآن، لننطلق في هذه الرحلة معًا! آمل أن تجدوا هذا المحتوى مفيدًا ومُلهمًا وقيّمًا. هيا بنا!

جدول المحتويات

مقدمة

Metal mechanical parts play a fundamental role in virtually every industry, from automotive and aerospace to heavy machinery and precision instruments. As global demands evolve, so do the design, manufacturing, and application of these essential components. With constant innovation in material science, production technologies, and market needs, keeping up with trends in metal mechanical parts is crucial for manufacturers and buyers alike.

في شركة Shanghai Leierwo Industry & Trade Co., Ltd., we continuously adapt to emerging trends to ensure we meet the ever-changing requirements of our clients. Specializing in investment casting, صب الرمل، و خدمات تصنيع الآلات باستخدام الحاسب الآلي, we are your most reliable partner in China for precision-engineered metal mechanical parts.

Trend 1: Increased Use of Lightweight Alloys in Metal Mechanical Parts

The demand for lightweight yet high-strength materials in metal mechanical parts has surged in recent years, especially in the automotive, aerospace, and transportation sectors. Lightweight alloys like aluminum, magnesium, and titanium have become the go-to materials due to their excellent strength-to-weight ratios, corrosion resistance, and thermal properties. By reducing the overall weight of mechanical systems, these materials significantly contribute to fuel savings and emission reduction, aligning with stricter environmental regulations and growing sustainability goals.

Moreover, the machining and casting technologies for lightweight alloys have advanced, allowing for more complex geometries and enhanced design flexibility. Manufacturers now benefit from improved performance without compromising safety or structural integrity. As governments and industries continue to prioritize energy-efficient solutions, lightweight alloys are expected to dominate the landscape of metal mechanical parts for years to come.

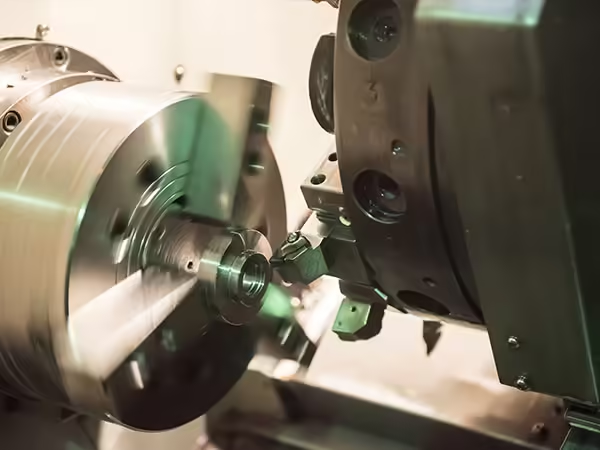

Trend 2: Adoption of Advanced CNC Machining Technologies

CNC machining remains a cornerstone of precision manufacturing, but the game has changed dramatically with the integration of smart manufacturing and automation. Today’s CNC machines are no longer just programmable tools—they are connected, intelligent systems that utilize multi-axis capabilities, high-speed spindles, and in-process quality monitoring. This allows manufacturers to produce highly complex metal mechanical parts with minimal error and exceptional consistency.

In particular, the adoption of digital twin technology and Internet of Things (IoT) integration enables real-time monitoring of tool wear, temperature, and production metrics. This improves traceability, reduces downtime, and enhances the scalability of operations. With growing emphasis on lean manufacturing and zero-defect policies, advanced CNC machining is not just a trend—it’s becoming the industry standard for precision metal mechanical parts production.

Trend 3: Rise of Customization in Metal Mechanical Parts

Mass production is gradually giving way to mass customization. Clients now seek tailored metal mechanical parts that align precisely with their operational requirements, environmental conditions, and performance goals. Whether it’s a unique valve component for a petrochemical system or a custom-engineered pump part for marine use, the demand for specialized solutions is growing across virtually every sector.

Customization goes beyond dimensions—it often includes material selection, surface treatment, tolerance level, and even packaging. At Leierwo, we work closely with our clients to design and manufacture metal mechanical parts that match their unique needs from the first prototype to final delivery. Our flexibility and engineering support ensure that your components perform optimally, whether you’re facing extreme temperatures, corrosive fluids, or mechanical stress.

Trend 4: Investment Casting’s Growing Dominance

Investment casting, also known as lost-wax casting, has taken a leading role in producing complex metal mechanical parts with minimal need for machining. This method is especially beneficial for intricate geometries, tight tolerances, and fine surface finishes. By allowing for the precise replication of complex molds, investment casting eliminates many of the limitations associated with traditional casting methods.

لييروو utilizes advanced investment casting processes, including composite technology and silica sol methods, which are ideal for carbon steel, alloy steel, and stainless steel components. These techniques reduce post-processing requirements, streamline production, and result in parts that meet the highest quality and dimensional standards. Industries such as defense, oil & gas, medical devices, and precision tools increasingly rely on this casting method for dependable performance in mission-critical applications.

Trend 5: Integration of Simulation and Digital Design Tools

The development of metal mechanical parts is no longer limited to physical prototyping. With the widespread availability of computer-aided engineering (CAE) and simulation software, engineers can now model, test, and validate parts virtually. Finite element analysis (FEA), computational fluid dynamics (CFD), and fatigue testing simulations provide insights into how a part will behave under various loads and conditions.

This digital-first approach drastically reduces the design cycle time, minimizes material waste, and enhances the final product’s reliability. By identifying and resolving design issues before production begins, companies save both time and cost. At Leierwo, we integrate CAD/CAM systems with our casting and machining operations to ensure that every part is optimized from design to delivery.

Trend 6: Sustainability and Eco-Friendly Manufacturing

As global attention shifts toward climate change and environmental stewardship, the metal mechanical parts industry must evolve accordingly. Sustainability has become a defining characteristic of modern manufacturing, influencing everything from material selection to energy consumption in production facilities. Manufacturers are now adopting low-waste techniques, using recyclable materials, and improving the energy efficiency of both casting and machining operations.

For example, sand casting with recyclable sand molds or investment casting using biodegradable waxes contribute to waste reduction. Meanwhile, CNC machines with energy-saving controls and real-time monitoring reduce power usage without compromising output. At Leierwo, we take pride in implementing green manufacturing principles—allowing our clients to meet their sustainability targets while still receiving high-performance, custom metal mechanical parts.

Trend 7: Quality Control and Real-Time Inspection Techniques

Precision is paramount in metal mechanical parts manufacturing, and today’s technology allows for unprecedented levels of accuracy. The integration of non-contact inspection systems, such as 3D scanning and coordinate measuring machines (CMM), into production lines enables real-time validation of part dimensions and tolerances. These tools provide immediate feedback, allowing for instant corrections and significantly reducing defective rates.

Advanced inspection techniques not only ensure compliance with industry standards but also instill confidence in clients who demand zero-defect deliveries. Leierwo incorporates rigorous quality control at every stage—from raw material inspection to final packaging. Our inspection systems are aligned with international certifications and help guarantee that every component we produce meets or exceeds your expectations for durability, fit, and function.

Comparative Overview of Trends in Metal Mechanical Parts

| Trend Number | Key Focus Area | Benefits for Manufacturers and Clients |

|---|---|---|

| 1 | Lightweight Alloys | Fuel efficiency, strength-to-weight optimization |

| 2 | CNC Machining Technologies | Precision, speed, cost-efficiency |

| 3 | التخصيص | Tailored functionality, market competitiveness |

| 4 | الاستثمار في الصب | Dimensional accuracy, reduced post-processing |

| 5 | Digital Design Tools | Faster prototyping, improved performance prediction |

| 6 | Sustainable Manufacturing | Compliance, brand value, environmental responsibility |

| 7 | Real-Time Inspection Techniques | Zero-defect production, reduced returns |

Why Leierwo Leads in Metal Mechanical Parts Solutions

Shanghai Leierwo Industry & Trade Co., Ltd. is at the forefront of metal mechanical parts innovation. As one of the largest precision casting and CNC machining manufacturers in China, we specialize in delivering high-quality carbon steel, alloy steel, and stainless steel components tailored to meet complex demands.

Our services include:

- الاستثمار في الصب: For complex, high-precision parts

- صب الرمل: For large-scale and custom-shaped parts

- تصنيع الآلات باستخدام الحاسب الآلي: For tight-tolerance, high-efficiency machining

Whether your project requires pump and valve components, engineering machinery parts, or custom metal fittings, Leierwo can deliver tailored solutions with consistency and excellence.

خاتمة

The landscape of metal mechanical parts is rapidly evolving, shaped by technological advances, environmental considerations, and the demand for customization. Businesses that stay informed and adapt to these trends will remain competitive and innovative in their respective industries.

Leierwo is committed to aligning with these trends by offering forward-thinking solutions, high-quality manufacturing services, and responsive support for every customer. If you’re seeking a trusted partner in precision casting and machining, Leierwo is your best choice.

الأسئلة الشائعة

What are metal mechanical parts used for?

Metal mechanical parts are used in various applications, including automotive engines, industrial pumps, construction machinery, and aerospace equipment. They serve critical structural and functional roles.

Why choose investment casting for metal mechanical parts?

Investment casting offers superior surface finish and dimensional accuracy, making it ideal for complex and high-precision components.

How long does Leierwo take to complete a project?

Typically, our production cycle is 3–5 weeks depending on part complexity. We also offer a free sample before mass production.

What materials can لييروو work with?

We offer castings in carbon steel, alloy steel, and stainless steel, and also provide CNC machining for a wide range of materials.

How do I get in touch with لييروو?

Please fill out our contact form on the website with your project details. You can also upload drawings and files directly.

فئات المنتجات

- أجزاء الصمامات

- أجزاء مضخة المياه

- أجزاء صندوق المحمل

- أجزاء الصب بالقالب

- منتجات مضخات الفولاذ المقاوم للصدأ

- منتجات مضخات الحديد الزهر

- قطع غيار الصمامات لاستخدام السيارات

- قطع غيار السيارات

- أجزاء الصمامات للاستخدام المدني

- قطع غيار مضخة التفريغ KF