6 Ball Valve Accessories Mistakes to Avoid

Welcome to My Blog!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

Table of Contents

Introduction

In the world of fluid control systems, ball valves play a critical role in ensuring seamless and efficient operations. From industrial plants to residential plumbing, these versatile components are often the go-to solution for flow regulation. However, an often overlooked aspect of valve installation and maintenance is the use of ball valve accessories. These accessories may appear minor, but their impact on system performance, longevity, and safety is enormous.

Unfortunately, many users make avoidable mistakes when selecting, installing, or maintaining ball valve accessories. Such oversights can lead to leaks, reduced performance, equipment failures, or even hazardous situations in more complex systems. In this article, we will highlight six common mistakes people make regarding these accessories. Along the way, we’ll explore how each error can negatively impact your operations and what steps you can take to avoid them.

Whether you’re a plant engineer, a maintenance technician, or simply someone interested in fluid control systems, this guide offers valuable insights into optimizing the performance of your system through better use of ball valve accessories.

Mistake 1: Using Incompatible Ball Valve Accessories

Why Compatibility Matters

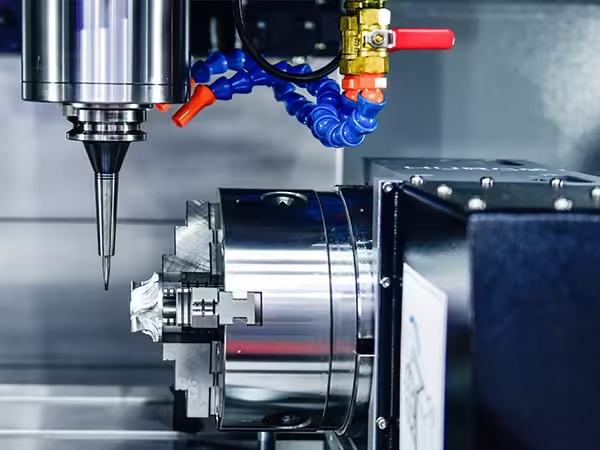

One of the most frequent and costly errors made when dealing with ball valve accessories is the use of incompatible parts. Accessories such as actuators, handles, locking devices, extension kits, or stem seals must match the valve’s size, pressure rating, and material specifications. Mismatched components can cause a host of problems, including mechanical failure, inefficient flow control, or even dangerous system leaks.

Material Compatibility

Material compatibility is especially crucial when working in specialized environments like chemical processing plants or high-pressure systems. For example, using aluminum accessories on stainless steel valves may lead to galvanic corrosion over time. Similarly, rubber seals in high-temperature settings may degrade quickly, leading to failure.

Pressure and Temperature Ratings

Every accessory has its limitations in terms of operating pressure and temperature. Always consult product data sheets and ensure that accessories match the operational parameters of the ball valve.

Mistake 2: Overlooking Proper Installation Techniques

The Importance of Correct Assembly

Improper installation is another common issue when it comes to ball valve accessories. Accessories such as actuators, limit switches, and position indicators require precise alignment and secure attachment. Failure to follow proper installation guidelines can lead to poor valve response, difficulty in operation, and potential safety hazards.

Common Installation Errors

- Over-tightening fasteners: This can damage mounting brackets or deform valve bodies.

- Ignoring manufacturer instructions: Each accessory may have specific installation steps that ensure optimal performance.

- Incorrect alignment: Misalignment of accessories can prevent the valve from fully opening or closing.

Training and Documentation

Providing your installation team with adequate training and detailed documentation is a proactive way to avoid these issues. Most reputable manufacturers offer comprehensive manuals and support materials for their ball valve accessories.

Mistake 3: Skipping Routine Maintenance for Accessories

Why Accessories Also Need Attention

While many maintenance programs focus on valves themselves, accessories are often neglected. Ball valve accessories such as gear operators, extension handles, and stem protectors are subjected to wear and tear and require regular inspection.

Consequences of Neglect

Failing to maintain accessories can lead to:

- Reduced lifespan of the entire valve assembly

- Inaccurate valve positioning

- Increased torque requirements

- Higher risk of leakage

Maintenance Recommendations

| Accessory Type | Maintenance Frequency | Common Issues | Recommended Actions |

|---|---|---|---|

| Manual Handles | Monthly | Loosening, corrosion | Tighten bolts, apply grease |

| Pneumatic Actuators | Quarterly | Air leaks, sluggish motion | Inspect seals, test operation |

| Limit Switches | Bi-annually | False signals | Test circuitry, replace worn parts |

| Locking Devices | Monthly | Rust, deformation | Clean, lubricate, check function |

| Extension Kits | Every 6 months | Misalignment, stiffness | Adjust fittings, replace bushings |

Regularly scheduled maintenance not only ensures consistent performance but also extends the life of both valves and their accessories.

Mistake 4: Choosing Accessories Without Considering Environmental Conditions

Environmental Suitability is Critical

Another pitfall in selecting ball valve accessories is neglecting the environment in which the valve operates. From extreme heat to corrosive chemicals or even outdoor weather, environmental factors must be taken into account.

Examples of Environmental Mismatch

- Indoor-rated actuators installed outdoors can lead to premature failure due to moisture and UV exposure.

- Non-sealed limit switches used in dusty environments may cause operational errors.

- Metal handles without insulation used in high-heat applications can cause burns during manual operation.

Best Practices

When selecting ball valve accessories, always ask these key questions:

- Is the accessory rated for outdoor use?

- Can it withstand exposure to chemicals or high humidity?

- Does it have protective coatings or enclosures for harsh environments?

Making informed decisions based on your environment ensures operational reliability and reduces the likelihood of unexpected failures.

Mistake 5: Ignoring the Role of Automation in Valve Accessories

Automation Integration Matters

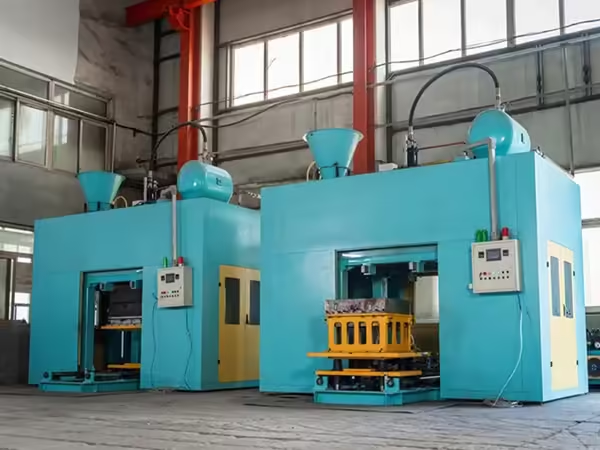

As industries evolve, automation has become a key component in many systems. Yet, some users continue to rely on outdated or manual accessories even when automated alternatives are available. Failing to modernize your ball valve accessories can limit performance and reduce overall system efficiency.

Automation Options

Accessories such as electric actuators, pneumatic controllers, and smart position indicators can be integrated into control systems for real-time monitoring and remote operation.

Benefits of Automation-Ready Accessories

- Improved accuracy in flow regulation

- Enhanced system safety through feedback signals

- Reduced human error

- Streamlined maintenance through diagnostics

Upgrade Strategy

When considering automation, assess your existing ball valves and identify compatible automation accessories. Many suppliers offer retrofit kits that allow you to upgrade without replacing the entire valve assembly.

Mistake 6: Buying Low-Quality or Generic Ball Valve Accessories

Price vs. Performance

The temptation to save costs by purchasing generic or low-quality ball valve accessories can result in significant long-term losses. These cheaper alternatives often lack proper testing, documentation, and durability under real-world conditions.

Hidden Costs

What appears to be a budget-friendly decision can quickly lead to:

- Higher maintenance costs

- Unexpected downtimes

- Frequent replacements

- Safety risks

How to Identify Quality Accessories

- Look for compliance with industry standards (e.g., ISO, ANSI)

- Review performance certifications

- Choose accessories with strong warranties and technical support

Quality ball valve accessories may cost more upfront, but they deliver better performance, reduce risks, and lower total ownership costs over time.

Conclusion

Ball valve accessories are more than just optional additions—they are vital components that directly impact system performance, reliability, and safety. From material compatibility to proper maintenance and automation readiness, every aspect of how these accessories are selected and managed plays a crucial role.

By understanding the six common mistakes covered in this article—using incompatible parts, poor installation, lack of maintenance, ignoring environmental factors, overlooking automation, and opting for low-quality accessories—you can significantly improve the longevity and efficiency of your valve systems.

Investing time and resources into selecting the right ball valve accessories and using them correctly will not only improve operational outcomes but also reduce long-term costs and maintenance demands.

FAQ

What are the most common ball valve accessories?

Some common accessories include actuators (electric or pneumatic), manual handles, locking devices, stem extensions, limit switches, and position indicators. These help in improving control, safety, and automation of the ball valve.

How often should ball valve accessories be maintained?

It depends on the type of accessory and the environment in which it’s used. Generally, maintenance intervals range from monthly for manual components to bi-annually for electrical accessories.

Can I use ball valve accessories from different brands?

It’s recommended to use accessories that are compatible and ideally from the same manufacturer to ensure proper fit and function. Always check specification sheets for compatibility.

Are all ball valve accessories suitable for high-pressure systems?

Not all accessories are rated for high-pressure environments. Ensure each component meets the pressure and temperature ratings of your system to avoid failures.

How can I improve the life of my ball valve accessories?

Choose high-quality accessories, install them correctly, conduct routine maintenance, and make sure they are suitable for the operational and environmental conditions of your system.

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF